Add AI Data Analytics to your existing IoT. No rebuild required.

We integrate an AI intelligence layer to your existing IoT infrastructure, transforming passive data collection into real-time analytics, anomaly detection, predictive insights, and more.

- Your devices, data pipelines, and platform.

- No hardware replacement.

Why add AI data analytics to your IoT

Data collection and visualization are the first steps toward true business intelligence. AI helps turn the data into decisions and predictions. Below is the value businesses can measure after introducing AI.

Higher operational efficiency

AI makes routine operational decisions automatically. Systems react to live conditions without waiting for operators. Fewer manual actions. Less delay. Lower waste.

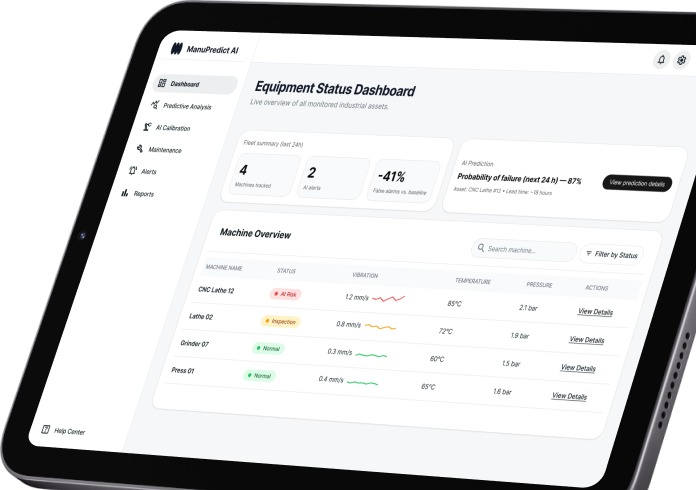

Predictive maintenance

AI finds early signs of equipment wear and abnormal behavior. Maintenance becomes planned. Downtime drops. Assets last longer.

Faster decisions

AI analyzes sensor data in real time and delivers ready-to-use insights. Teams act immediately instead of waiting for reports.

Safety and risk control

AI monitors operational signals continuously and detects abnormal patterns. Risks are identified early. Incidents are prevented.

Energy and cost optimization

AI analyzes usage patterns and adjusts systems automatically. Energy waste decreases. Operating costs go down.

Scalable intelligence

More devices mean more data. More data improves model accuracy. The system becomes smarter as it grows.

Let’s discuss your AIoT data analytics project!

Drop us a line and discuss your project within 1 business day with SumatoSoft AIoT experts.

Capabilities we unlock by adding AI data analytics to IoT

Below are the AI capabilities we add on top of your existing IoT system – each designed to solve concrete operational problems, improve performance, and enable automation without changing your current infrastructure.

Anomaly detection

Capability

Automatic detection of behavior that deviates from normal operating patterns.

Input

Historical data to establish normal ranges and live data to compare against them.

Business impact

Thresholds catch only obvious failures. Many problems begin as subtle changes that stay within limits.

Operational outcome

The system flags situations like unusual vibration patterns, slow pressure loss, abnormal power draw, or irregular device communication – before alarms or failures occur.

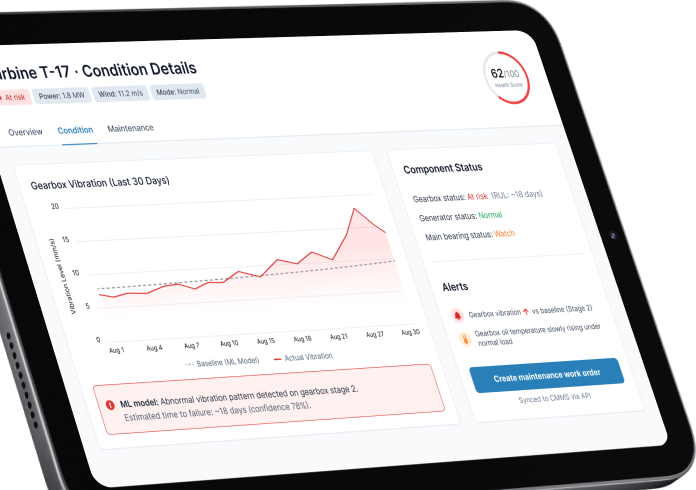

Predictive insights

Capability

Forecasts of future equipment states and operational outcomes.

Input

Time-series data with sufficient history and consistency.

Business impact

Knowing that something will fail soon allows planning instead of reacting under pressure.

Operational outcome

The system estimates the remaining useful life of components, predicts the probability of failure in the next days or weeks, or forecasts performance degradation based on current trends.

Automated actions

Capability

Execution of predefined responses without manual intervention.

Input

Clear action rules, confidence thresholds, and approval logic.

Business impact

Manual responses are slow and inconsistent at scale.

Operational outcome

The system adjusts setpoints, throttles equipment, isolates a device, triggers a maintenance ticket, or sends commands to downstream systems automatically.

Continuous optimization

Capability

Ongoing adjustment of system parameters to maintain optimal performance.

Input

Defined optimization goals and operational constraints.

Business impact

Optimal settings change as load, environment, or usage patterns change.

Operational outcome

The system tunes parameters such as energy consumption per unit, production speed, or resource allocation to keep performance within target ranges.

Computer vision

Capability

Automated analysis of image and video streams.

Input

Cameras or visual sensors and labeled examples or detection criteria.

Business impact

Visual inspection does not scale and is inconsistent.

Operational outcome

The system detects surface defects, missing components, safety violations, or unauthorized access directly from camera feeds.

Natural language processing

Capability

Structured insights extracted from operational text data.

Input

Access to logs, alerts, tickets, or operational notes.

Business impact

Text data is hard to analyze at scale and often ignored.

Operational outcome

The system groups similar incidents, highlights recurring error patterns, summarizes long logs, and links text events to device or system behavior.

Recent AIoT software we developed

IoT apps for controlling an air conditioning system

AI-powered predictive maintenance for a large industrial manufacturer

IoT- and ML-based predictive wind farm maintenance

Seamless integration. No re-engineering required.

We add AI on top of your existing IoT system without touching production-critical components. Your devices, gateways, data pipelines, and dashboards remain intact. The AI layer operates independently, consuming data through secure connectors and APIs. In practice, this means:

No device replacement or firmware rewrite

We work with the data your devices already produce. The AI layer connects to existing gateways, brokers, or data streams and analyzes telemetry as is. Firmware, protocols, and device logic remain unchanged.

No platform migration or vendor lock-in

The AI layer integrates through standard APIs and message interfaces. It runs as a separate component and does not replace your IoT platform. You keep control over data, infrastructure, and vendors.

No downtime for running operations

AI is deployed in parallel with production systems. We start in read-only mode, validate results, and enable actions only after testing. Rollback is instant because core systems stay untouched.

From pilot to enterprise rollout

The same architecture used in the pilot is reused at scale. No throwaway prototypes. What works on 10 devices works on 10,000.

Quick and reliable results

We start with a limited scope – one asset group, one site, or one use case. You measure real KPIs. Our approach reduces integration risk, shortens time to value, and lets you validate results before scaling.

Use cases & industry applications

Manufacturing & industrial environments

Factories operate nonstop and often utilize a combination of new systems and older machines. AI must handle machine-to-machine differences, changing workloads, and gradual wear, and it must connect safely to MES/SCADA and other shop-floor systems. We build AIoT solutions that detect early signs of trouble, keep alerts relevant, and explain findings in plain terms, helping teams prevent stoppages, maintain quality stability, and plan maintenance without interrupting production.

Energy & utilities

In energy and utilities, safety and stable operations are paramount, and rules and audits are integral to daily work. Data comes from many sites, network conditions vary, and some decisions must be made quickly. We deliver AIoT systems that can run at the edge or in the cloud, focusing on fault spotting and robust operation, and keeping AI actions within clear limits, so teams can identify issues sooner, reduce losses, and maintain reliable services.

Logistics & fleet operations

Logistics is shaped by movement, weather, traffic, and changing schedules. Data can be late, missing, or inconsistent, so AI must still work under uncertainty. We build AIoT solutions that utilize the data you have, blend predictions with practical rules, and generate actions that people can execute, helping to reduce delays, improve vehicle and asset utilization, and lower fuel and maintenance costs.

Smart buildings & facilities

Buildings must conserve energy while maintaining comfort and safety. Many sites utilize equipment from various vendors and generations, which makes integration more challenging. We integrate AI on top of existing building systems, maintain automation within established comfort and safety boundaries, and make actions easy to track and reverse, so energy waste decreases while operations remain predictable for facility teams.

Retail & physical environments

Retail has tight budgets and big differences between stores. Data privacy expectations are high, and teams need quick signals they can act on. We utilize AIoT to transform store sensors and operational data into clear, timely insights, helping to reduce shrinkage, improve replenishment and staffing, and enhance the in-store experience without collecting more data than necessary.

Healthcare & connected devices

Healthcare requires high accuracy, clear reasoning, and strict handling of sensitive data. AI outputs must support clinicians and operations teams in ways that enable them to review and justify their decisions. We build AIoT systems for monitoring and issuing early warnings, complete with full logging and governance, to help improve care and efficiency while staying aligned with compliance needs.

Manufacturing & industrial environments

Factories operate nonstop and often utilize a combination of new systems and older machines. AI must handle machine-to-machine differences, changing workloads, and gradual wear, and it must connect safely to MES/SCADA and other shop-floor systems. We build AIoT solutions that detect early signs of trouble, keep alerts relevant, and explain findings in plain terms, helping teams prevent stoppages, maintain quality stability, and plan maintenance without interrupting production.

Energy & utilities

In energy and utilities, safety and stable operations are paramount, and rules and audits are integral to daily work. Data comes from many sites, network conditions vary, and some decisions must be made quickly. We deliver AIoT systems that can run at the edge or in the cloud, focusing on fault spotting and robust operation, and keeping AI actions within clear limits, so teams can identify issues sooner, reduce losses, and maintain reliable services.

Logistics & fleet operations

Logistics is shaped by movement, weather, traffic, and changing schedules. Data can be late, missing, or inconsistent, so AI must still work under uncertainty. We build AIoT solutions that utilize the data you have, blend predictions with practical rules, and generate actions that people can execute, helping to reduce delays, improve vehicle and asset utilization, and lower fuel and maintenance costs.

Smart buildings & facilities

Buildings must conserve energy while maintaining comfort and safety. Many sites utilize equipment from various vendors and generations, which makes integration more challenging. We integrate AI on top of existing building systems, maintain automation within established comfort and safety boundaries, and make actions easy to track and reverse, so energy waste decreases while operations remain predictable for facility teams.

Retail & physical environments

Retail has tight budgets and big differences between stores. Data privacy expectations are high, and teams need quick signals they can act on. We utilize AIoT to transform store sensors and operational data into clear, timely insights, helping to reduce shrinkage, improve replenishment and staffing, and enhance the in-store experience without collecting more data than necessary.

Healthcare & connected devices

Healthcare requires high accuracy, clear reasoning, and strict handling of sensitive data. AI outputs must support clinicians and operations teams in ways that enable them to review and justify their decisions. We build AIoT systems for monitoring and issuing early warnings, complete with full logging and governance, to help improve care and efficiency while staying aligned with compliance needs.

Is your IoT ready for AI data?

Most IoT systems already collect enough data to benefit from AI. The key question is not whether AI is possible, but whether your existing data and operations can support AI. Below is our checklist, which we use to assess the business readiness of adding an AI layer.

Data availability

Your devices already send data into one or more systems – an IoT platform, database, message broker, or data lake. The data may be spread across tools, but it exists and can be accessed.

AI works only with data it can reliably read. When telemetry is already collected and reachable, AI can be added without changing devices or pipelines.

In most businesses with IoT, this condition is already met.

Data volume and history

You have accumulated historical data that shows how devices behave over time.

This data is used for AI learning from repeated patterns. Without a history, models cannot distinguish between normal behavior and early signs of degradation or failure.

In practice, weeks or months of consistent data are enough. A long history improves accuracy, but it is not a strict requirement.

Data quality

Sensor readings are generally understandable: units are known, timestamps make sense, and gaps or noise are expected and explainable. AI does not require perfect data, but it must be able to distinguish between what is meaningful and what is random variation.

Most enterprise IoT data contains noise. As long as operational data behavior is stable and documented, AI can work with it.

Latency requirements

There is a clear understanding of which reactions must happen immediately and which can tolerate some delay. Latency requirements determine where AI should run – directly on devices, at the edge, or in the cloud.

In real systems, both fast reactions and slower analysis usually coexist. AI is applied accordingly, without forcing a single deployment model.

Operational context

IoT data is tied to real-world meaning: devices map to assets, locations, or processes, and standard operating behavior is understood. Context plays a significant role in AI effectiveness, as it should understand what a signal represents and its corresponding impact.

Most enterprises already maintain this context in CMMS, ERP, asset registries, or configuration systems, even if it is not centralized.

Actionability

When abnormal behavior appears, there is an existing response – manual adjustment, maintenance dispatch, escalation, or workflow trigger. AI creates value only when insights lead to action. Analysis alone does not change outcomes.

In practice, AI replaces manual monitoring and analysis, while decision ownership remains with people or existing systems.

Quick playbook: planning AIoT development project [pdf]

Get a free playbook that will help you plan the project and find the right AIoT development partner. No email required.

Trust and risk reduction by design

AI adoption should be predictable, controllable, and safe to operate in production. Our AIoT approach is built to reduce risk at every stage.

No-disruption guarantee

AI is added as a separate layer and does not interfere with production systems. Deployment starts in observation mode, without automated actions. Results are validated first, and automation is enabled only when approved.

What this gives you: If AI is paused or rolled back, core systems continue running unchanged.

Security, data ownership, and compliance

Your data remains yours. AI connects to existing systems using secure, least-privilege access. Data processing can run in the cloud, on your infrastructure, or at the edge, depending on your security and compliance requirements.

What this gives you: We design for encrypted transport and storage, per-device identity, and audit-ready access controls. Industry and regional compliance requirements are addressed at the architecture level.

Explainability and human control

AI decisions are traceable to input data and model outputs. Thresholds, confidence levels, and decision rules are defined upfront.

Automation is optional and configurable. Humans remain in control of critical actions, approvals, and overrides.

What this gives you: AI that supports decisions instead of acting as a black box.

Scalable and predictable operations

AI models, integrations, and updates follow controlled release and rollback processes. Monitoring is in place for data drift, model behavior, and system health.

What this gives you: stable AI operations at enterprise scale.

KPIs we improve

We measure AI implementation and ensure it brings tangible results from day one. We design AI layers that are designed to impact the KPIs enterprises already use to manage performance, risk, and cost. These improvements compound over time. As more data flows through the system, accuracy increases, and operational variance decreases.

Downtime and availability

Early detection and prediction reduce unplanned stops and stabilize operations.

Impacted metrics:

MTBF, unplanned downtime, availability %

Mean time to repair (MTTR)

Issues are detected earlier and diagnosed faster, so teams spend less time investigating and more time fixing.

Impacted metrics:

MTTR, incident resolution time

Asset performance and utilization

AI identifies underperforming assets and inefficient operating modes.

Impacted metrics:

OEE, asset utilization rate, throughput

Energy and resource efficiency

Continuous optimization reduces waste without affecting output or safety.

Impacted metrics:

Energy per unit, operating cost per unit, emissions intensity

Quality and defect rates

Anomalies and deviations are caught before they propagate into defects.

Impacted metrics:

Scrap rate, defect rate, rework volume

SLA and service reliability

Earlier detection and faster response reduce SLA breaches and customer impact.

Impacted metrics:

SLA compliance, incident frequency, customer-impacting events

Operational workload

AI replaces manual monitoring and analysis, reducing noise and cognitive load.

Impacted metrics:

Alerts per operator, manual checks, and investigation time

Downtime and availability

Early detection and prediction reduce unplanned stops and stabilize operations.

Impacted metrics:

MTBF, unplanned downtime, availability %

Mean time to repair (MTTR)

Issues are detected earlier and diagnosed faster, so teams spend less time investigating and more time fixing.

Impacted metrics:

MTTR, incident resolution time

Asset performance and utilization

AI identifies underperforming assets and inefficient operating modes.

Impacted metrics:

OEE, asset utilization rate, throughput

Energy and resource efficiency

Continuous optimization reduces waste without affecting output or safety.

Impacted metrics:

Energy per unit, operating cost per unit, emissions intensity

Quality and defect rates

Anomalies and deviations are caught before they propagate into defects.

Impacted metrics:

Scrap rate, defect rate, rework volume

SLA and service reliability

Earlier detection and faster response reduce SLA breaches and customer impact.

Impacted metrics:

SLA compliance, incident frequency, customer-impacting events

Operational workload

AI replaces manual monitoring and analysis, reducing noise and cognitive load.

Impacted metrics:

Alerts per operator, manual checks, and investigation time

Why enterprises trust SumatoSoft

Since 2012, we’ve helped enterprises make better use of their IoT data. Over the years, we’ve built, integrated, and scaled connected systems. Along the way, we distilled clear, non-negotiable practices for reliable delivery that we apply when providing our services. Today, we’re a trusted software partner for businesses in 26 countries, including the US.

We are experts with vast experience

Security mastery

We provide reliable and predictable delivery

Transparency & ongoing support

Industrial integrations that don’t break production

For 14+ years, we have proudly taken responsibility for your AIoT projects!

Awards & Recognitions

Let’s start

If you have any questions, email us info@sumatosoft.com