Case Study: IoT- and ML-based predictive wind farm maintenance

An energy company in Germany operates an onshore wind farm with several dozen turbines. Gearbox and generator failures resulted in downtime, costly emergency repairs, and crane calls during adverse weather. SumatoSoft developed a predictive maintenance system that collects data from turbines, analyzes the condition of key components, and helps plan maintenance. The Client reduced unplanned downtime and lowered maintenance costs without replacing the existing SCADA system.

Project details:

About the Client:

The Client is an energy company that operates an onshore wind farm in Germany. The site includes several dozen turbines with multi-stage gearboxes and high-power generators.

Location: Germany

Industry: Renewable energy

Team size: 7 specialists (system architect/team lead, business analyst/product owner, 2 backend developers, frontend developer, ML engineer, QA engineer)

Project duration: 10+ months

Business сhallenge

The Client needed to maintain their wind farm’s high availability while keeping maintenance costs under control. The turbines are located over a large area and are not always accessible. Replacing components in the nacelle requires a crane and a dedicated crew.

The company used scheduled maintenance based on turbine operating hours and basic SCADA alarms. Damage was often detected only after the turbine had entered emergency mode. The gearbox or generator had to be replaced within a short timeframe. This led to long downtimes and increased repair costs.

Additional requirements:

- use the existing SCADA system and communication network,

- do not replace turbine controllers and sensors unless necessary,

- account for unstable communication on the part of the site,

- provide a simple interface for operations and maintenance planning engineers.

Our solution

Working with the Client’s engineers, we developed a predictive maintenance system that operates on top of the current infrastructure. We identified a set of critical components and parameters, integrated data from existing vibration and temperature sensors, and added missing data points.

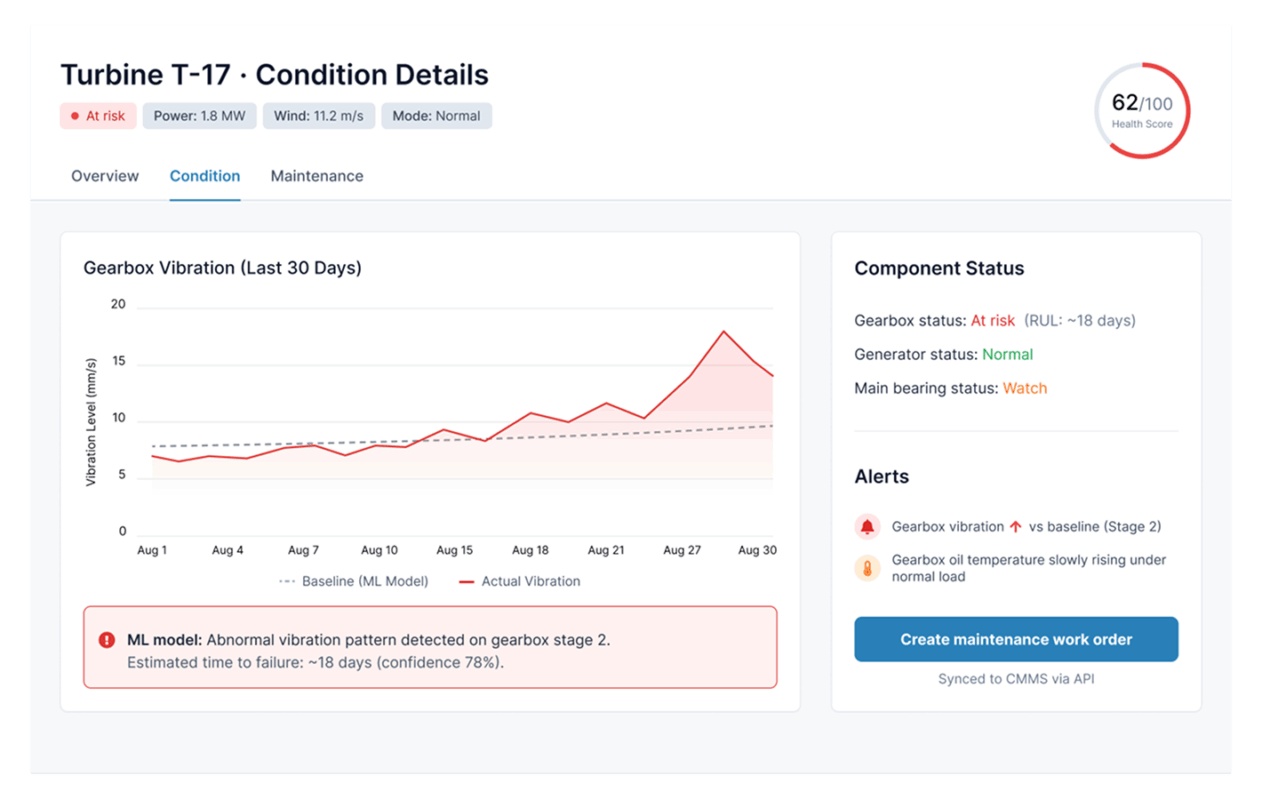

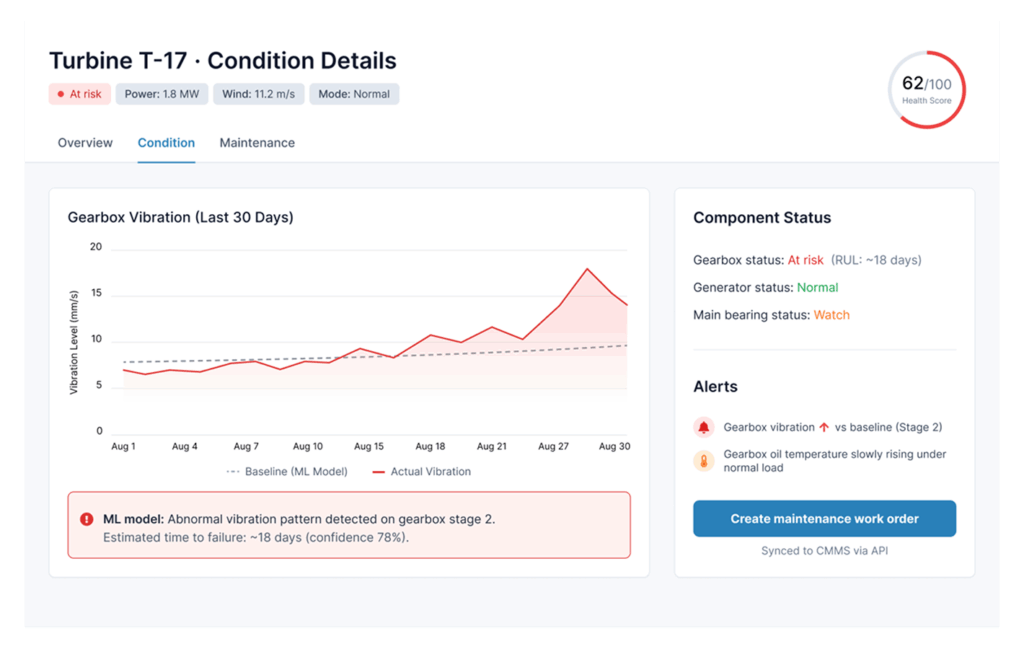

Data from the turbines is transmitted via IoT gateways to the cloud platform. We implemented data ingestion, cleaning, and normalization for all turbines. The analytics module operates on this layer. It utilizes machine learning models and anomaly detection algorithms. They generate a baseline profile of component performance under different wind and load conditions and monitor for deviations that indicate wear.

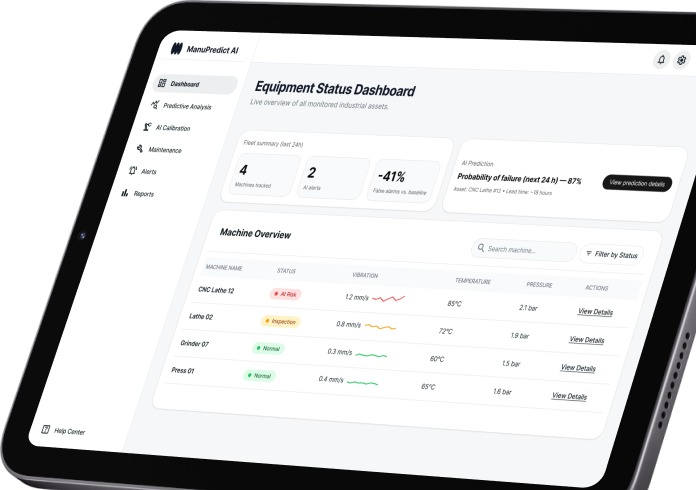

Monitoring and analytics platform

Engineers can view the turbine status in a web application: a site map, a turbine health summary, and details for each component. Confirmed issues can be converted into tickets in the maintenance planning system via an API, and work can be scheduled in convenient windows.

Additional features:

- profiles of “normal” node behavior, taking into account wind speed and load,

- detection of anomalies in vibration, temperature, and generator current,

- wind farm map with turbine status and failure risk filters,

- data buffering on the gateway during connection loss and subsequent transmission.

Business value

Before:

- Gearbox and generator failures occurred without early warning.

- Turbines were idle while the Client waited for a crane, parts, and a weather window.

- It was difficult for the operations team to assess the components’ actual condition.

- Maintenance was performed based on operating hours, without accounting for actual wear and tear.

After:

- The system provides early warning signs of issues based on sensor data.

- Maintenance is scheduled during periods of low output and better weather.

- Engineers can see turbine condition and priority risks in a single interface.

- Maintenance is performed based on actual wear and tear, reducing unplanned downtime and emergency repair costs.