IoT integration into legacy systems (OT/IT)

Connect your existing equipment and core systems to real-time data and automation, while maintaining stability and modernizing around it.

When IoT integration with legacy systems is the right choice

Integrating IoT into your existing legacy system is a good fit if you recognize these situations:

Start your transformation

Ready to scale? Let’s discuss your legacy setup and build a custom IoT bridge today.

What we integrate

We connect the parts you already have for clean data flow.

Operational technology

PLCs, sensors, machines, gateways, industrial networks: we collect signals from legacy and mixed-vendor equipment without changing how it runs.

Integration layer

Protocol translation, normalization, buffering, rules, edge computing: this layer turns device chatter into stable, versioned data your systems can trust.

IT and cloud

ERP, MES, SCADA, CMMS, data warehouse, BI, data lake, alerting, ticketing: we deliver telemetry and events where they drive actions, e.g., reports, maintenance, and operations.

For 14+ years, we have proudly taken responsibility for your IoT projects!

Built for legacy environments

Legacy IoT projects fail on predictable points: protocol gaps, security boundaries, and data volume. We design around these constraints and keep the core system stable.

Integration that stays maintainable

You get a connector layer with clear interfaces, documented mappings, and version control, so the integration can evolve without breaking production.

Production-safe delivery

We work in stages: discovery, blueprint, pilot, scale, and operations. Each step has acceptance criteria and a rollback path. Monitoring is part of the initial release.

IoT is a core service line

IoT development is a dedicated service area at SumatoSoft, with related offerings like IoT security and compliance.

Awards & Recognitions

Request a technical quote

Get a transparent breakdown of the costs and timelines involved in retrofitting your systems.

Benefits of IoT integration in legacy systems

Modernization without ripping out what still works

Legacy systems often stay in place for a reason. They run critical processes and have years of proven stability. IoT integration lets you add new data flows and automation around the core system while keeping its logic intact.

It’s not a multi-million rip-and-replace project

Replacing an industrial control system, a plant-wide SCADA stack, or a core back-office platform can take years and force long production stops. Integration gives you a smaller, controlled scope. You extend asset life and protect prior investment instead of restarting from zero.

Blind assets become measurable

Many older machines expose only basic signals or require manual checks. IoT integration adds continuous telemetry and events: machine health, energy use, throughput, and anomalies. Once the data is available, teams can act on it fast.

Fast operational wins from new data

Real-time visibility opens practical improvements that were impossible before. Predictive maintenance becomes realistic. Downtime analysis gets cleaner. Energy spikes stop being a mystery and start being actionable.

Compliance and reliability are kept with minimal disruption

In regulated environments, the legacy system can be part of an audited process. Full replacement adds validation risk and can break established controls. Integration lets you modernize monitoring and reporting on the periphery while preserving the proven system of record.

Integration fragility is reduced over time

A structured integration layer replaces ad-hoc “translator per device” setups. You get a consistent data model, versioned connectors, monitoring, and clear ownership boundaries. The result is a system you can change safely as the estate grows.

Security and reliability of legacy IoT integrations

SumatoSoft ensures that IoT security and reliability measures are built in from day one.

- Network segmentation and least-privilege access

- Device identity, certificates or keys, secure update strategy when relevant

- Encryption in transit and audit logs

- Monitoring, retries, and buffering for unstable links

- Backward-compatible changes, rollback plans, testing in staging, or a digital twin when available

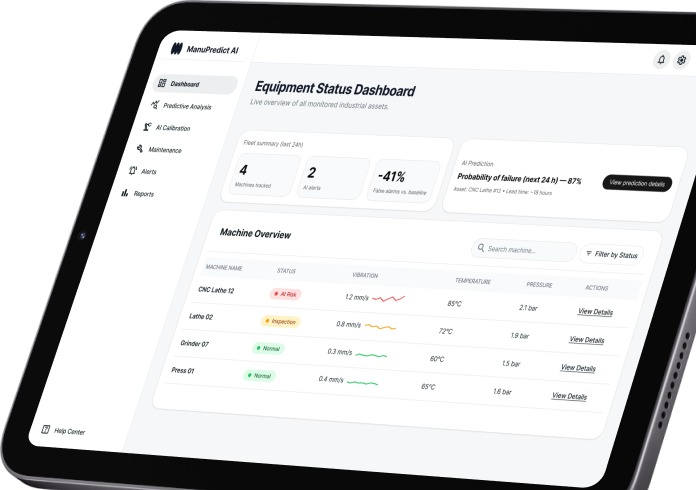

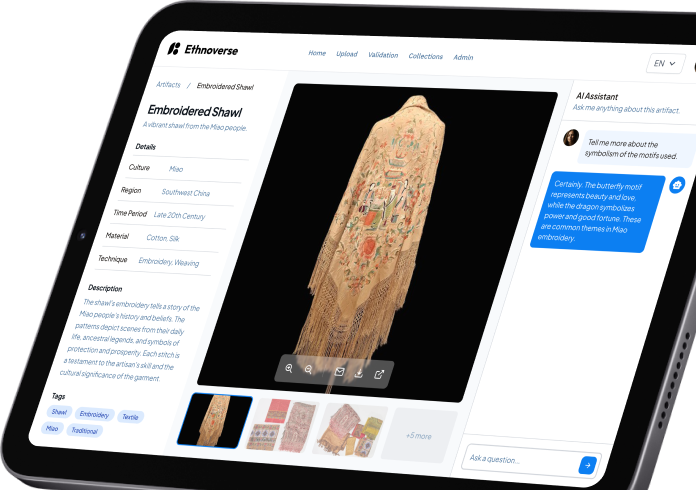

Our recent works

Integration patterns

These are common setups we implement. Each one solves a specific bottleneck.

- Legacy machine → gateway → MQTT/HTTPS → cloud/analytics

You keep the machine controls intact. The gateway publishes normalized telemetry.

As a result, you get real-time monitoring and analytics without interfering with the PLC logic.

- SCADA historian → event stream → data warehouse

We extract historical signals and convert them into a stream and curated tables.

As a result, plant data becomes usable for BI, trends, and cross-site reporting.

- MES/ERP sync for production + maintenance context

We align orders, shifts, batches, and asset metadata with operational events.

As a result, downtime and quality issues get a business context, and you can act on them.

- Condition monitoring → CMMS work orders

Sensors or existing signals trigger rules and maintenance workflows.

As a result, you get earlier detection of issues with devices and fewer maintenance surprises.

- Asset tracking → inventory/warehouse system

Tags and readers feed location and state changes into inventory logic.

As a result, the network loses fewer assets, audits faster, and gets a clearer chain of custody.

- Edge rules → alerts → ticketing (ServiceNow, Jira, and more)

We evaluate thresholds and anomalies at the edge or in the pipeline.

As a result, you receive actionable alerts with routing, deduplication, and traceability.

Optimize your operations

Connect your legacy assets to a modern dashboard and start reducing downtime immediately.

Results of integrating IoT with your legacy solution

After we implement your legacy system with IoT, you get the following artifacts that you own and maintain:

- Integration architecture and data flow map

- Protocol and connector layer (drivers, adapters)

- Canonical data model and mappings

- Pipelines (edge or cloud) and storage schema

- Monitoring dashboards and alerts

- Runbooks and handover documentation

SumatoSoft rolls out IoT integration without disrupting production

We inventory the systems, map protocols, data owners, network zones, and operational constraints, and define what cannot change.

We design a canonical data model and mappings from each source system, define latency targets, data frequency, retention, and SLAs, and decide where processing happens: on the edge, on-prem, or in a cloud.

We start small to prove two things: value and stability. The pilot validates data quality, integration behavior under load, and production safety.

We convert what worked into templates and repeatable patterns, version connectors and mappings, add monitoring coverage, and set change control rules for releases.

We set up observability, incident response, and update procedures. The integration stays maintainable as systems, vendors, and requirements change.

What changes when the IoT integration is in place

Unified telemetry across sites and vendors

Faster root-cause analysis with fewer blind spots

Automated maintenance triggers and cleaner work orders

Data you can trust for analytics and forecasting

Let’s start

If you have any questions, email us info@sumatosoft.com

Frequently asked questions

Do we need to replace equipment when integrating IoT with our legacy system?

No. The goal is to integrate around what still works. We add gateways, sensors, or connectors where needed.

How do you handle proprietary protocols when integrating IoT?

We use available drivers when they exist. When they don’t, we build adapters and document the interface and mappings.

Can you work with air-gapped networks?

Yes. We can design on-prem or segmented deployments that keep the core isolated and control what crosses boundaries.

What’s a typical pilot timeline?

A pilot for legacy IoT integration usually takes 8–12 weeks end-to-end.

How do you monitor integrations in production?

We implement logs, metrics, health checks, and alerting. You can see connector status, data latency, error rates, and retries. We can also develop a data analysis solution for you.