AI-Powered IoT: The Next Wave of Innovation

AI in IoT (AIoT) stops being hype the moment it saves you money, time, or risk. This article kicks off our series on AI-Powered IoT – a practice-based examination of real cases where Artificial Intelligence meets the Internet of Things. We’ll take a decision-first approach to assess and understand how to implement AIoT in your business.

The series includes one general article (this one) and four industry-specific deep dives with real-life cases and ROI breakdowns:

What you’ll get

- real-life use cases – cases in manufacturing, logistics, agriculture, and other industries with ROI calculations and details of AIoT implementation;

- go/no-go signals – a short self-assessment to decide if AI will help your IoT now or later;

- core concepts, fast – rule-based vs. ML vs. DL vs. GenAI – what to use when;

- ROI and KPIs – examples, benchmarks, how to measure;

- business case math – a simple formula to quantify benefits, payback, and NPV.

No fluff, no vendor pitch – just examples, tools, tables, and steps you can apply today from practitioners from SumatoSoft with over 13 years of expertise in custom IoT development.

The starting point of our article is to understand the core concepts of AIoT.

Understanding the Core Concepts

- What is AIoT?

- IoT basics.

- What AI types are used for IoT?

The convergence of Artificial Intelligence (AI) and the Internet of Things (IoT) is called AIoT. Its power can be simply described through the following scheme: the Internet of Things collects data, and AI analyzes it in real time.

The integration of AIoT turns IoT into an intelligent, self-optimizing system that delivers multiple benefits that we will examine later on in the article.

IoT Basics

The fundamental nature of IoT consists of a network which connects devices that sense and communicate and act. The systems convert raw signals into meaningful actions through a combination of hardware components and connectivity options and data processing flows.

Its core elements are:

- devices: sensors (temperature, vibration, image, etc.), actuators (valves, motors), and controllers (MCU/PLC/SoC). Examples are IoT devices for the healthcare industry;

- communication channels: short-range (BLE, Zigbee, Wi-Fi), LPWAN (LoRaWAN, NB-IoT, LTE-M), broadband (4G/5G, Ethernet), industrial buses (Modbus, CAN, OPC UA).

- data flows.

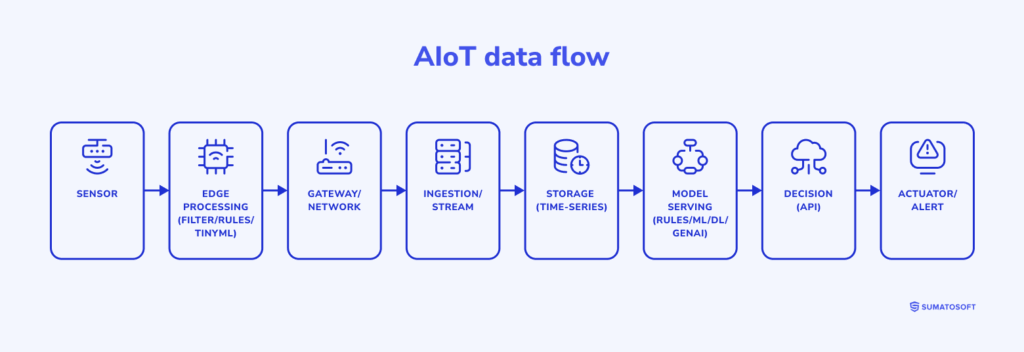

The IoT data flow starts with sensors that gather unprocessed measurements, such as temperature readings, vibration data, or image information. The edge processing stage performs basic filtering and some rule-based logic.

The next step is up to lightweight AI models (TinyML) that process data while reducing noise and latency. The gateway or network transports the data to an ingestion layer, which streams it into time-series storage.

Regarding synergy with AI, AI models analyze the data to detect patterns while generating predictions and developing insights. The system uses an API to send decisions that activate actuators or produce alerts to finish the sensing-action cycle.

Here is a visualized minimal loop:

AI Types For IoT – What to Use And When

AI in IoT can take many forms, from simple rule-based logic to advanced deep learning and generative models. Each type has its strengths, limitations, and ideal use cases depending on the data, performance needs, and computing resources available.

Let’s examine them from the perspective of:

- type – the category of AI approach;

- best for;

- data need – the amount, quality, and type of data required for the approach to work effectively;

- footprint / latency – the computing resources it needs (memory, CPU/GPU) and how quickly it can produce results, especially for real-time IoT use cases;

- limits – the main constraints, risks, or situations where the approach is less effective or impractical.

| Type | What it is | Best for | Data need | Footprint / latency | Limits |

|---|---|---|---|---|---|

| Rule-based (deterministic) | IF-THEN logic, thresholds, finite-state machines | Clear physics, safety interlocks, fast rejects | None beyond current signals | Tiny (MCU/PLC). µs-ms. | Brittle to drift/variance; many false alarms. |

| Machine Learning (classic ML) | Trees, linear/logistic, SVM, k-NN | Anomaly detection, quality scoring, forecasting | 3-12+ months of labeled or proxy-labeled data | Small-medium (edge gateway/cloud). ms-s. | Feature engineering required; moderate accuracy ceilings. |

| Deep Learning (DL) | Neural nets: CNN/RNN/Transformers | Complex sensor fusion (vision, audio, vibration), sequence modeling | Lots of data; often labeled; may need augmentation | Medium-large (GPU/NPU). ms-100s ms at edge, s in cloud. | Heavier compute; harder to explain; needs MLOps. |

| Generative AI | LLMs, diffusion, generative time-series | Tech ops copilots, NL runbooks, incident chat, code/rule suggestions, synthetic data | Text/logs or domain corpora; prompt design | Cloud/edge with accelerators. interactive-seconds | Hallucinations; governance & privacy; not for hard real-time. |

Quick chooser on AI approach:

- Need instant, predictable actions on tiny hardware – start Rule-based (optionally add TinyML).

- Fighting false alarms or subtle patterns – ML first; it’s lighter and explainable.

- Working with high-dimensional signals (vision, acoustics, multi-sensor) – DL.

- Want human-in-the-loop operations, NL interfaces, or auto-docs/runbooks – Generative AI (with safeguards).

Choosing the Right AIoT Architecture

There are 3 architecture types:

- edge AI;

- cloud AI;

- hybrid AI.

This choice is about picking the most suitable architecture for your specific business case rather than picking the best one.

Edge AI

Models run on the device/PLC/gateway, so decisions happen locally in tens of milliseconds. You send summaries upstream, which saves bandwidth and keeps sensitive data on-site. Best when connectivity is weak or actions must be instant.

Use when:

- actions must happen in under 100 ms or require deterministic control loops;

- connectivity is costly, unreliable, or sites must run offline;

- sensitive data needs to stay on-site for residency or compliance reasons;

- bandwidth is limited, you can pre-filter data and send only summaries.

Cloud AI

Devices stream data to the cloud, where models are trained and served centrally. You get powerful models, cross-fleet analytics, and rich logs, but action latency depends on the network. Best for non-real-time decisions and fleet-wide insights.

Use when:

- you need complex models or frequent retraining at scale;

- cross-fleet analytics and global optimization matter more than immediacy;

- decisions are non-real-time (hundreds of ms → seconds+);

- you want centralized ops: rich logs, A/B tests, autoscaling.

Hybrid AI

Fast, privacy-sensitive decisions run at the edge; heavy training and fleet learning live in the cloud. You filter and uplift data selectively, combining low latency with centralized control. This is the default pattern once pilots scale.

Use when (default beyond pilots):

- you need instant local control + centralized learning/management;

- mixed privacy/residency: keep sensitive parts local, learn in cloud;

- you want to cut bandwidth via edge filtering but keep fleet insights;

- must degrade gracefully during WAN outages (fallback/cached decisions).

How To Choose the AIoT Architecture

Start with your constraints: target latency, bandwidth budget, data sensitivity, offline tolerance, and model size. If you have a technical specialist on site, ask him to answer the following questions:

Target latency

- What is the action the model triggers, and what is the max acceptable end-to-end delay (p95) from signal to action? [ms]

- Is there a hard safety limit (cutoff) for this action? [ms]

- Are humans in the loop (UI/voice)? What delay is acceptable without hurting UX? [ms]

- How much jitter can the system tolerate? [ms]

Bandwidth budget

- What is your available uplink/downlink per site (typical/peak)? [Mbps]

- What’s the cost per GB (and any monthly caps/fair-use limits)? [$ / GB, cap GB]

- How much data does one device produce (raw vs. filtered)? [KB/s, events/s]

- What’s the monthly cost ceiling per site you can allocate to telemetry/AI? [$]

Data sensitivity

- Which fields are PII/PHI/IP or otherwise sensitive? [list]

- Any data residency constraints (on-prem/in-country/region)? [yes/no + region]

- Required retention period and minimization rules? [days/months]

- Mandatory encryption/audit standards (e.g., GDPR, HIPAA, ISO 27001, FIPS)? [list]

Offline tolerance

- How often and how long do WAN outages occur? [events/month, minutes/event]

- How long can you operate without WAN before service degrades? [minutes/hours/days]

- What is the required degraded mode during outage (full/limited/stop)? [choose]

- How much data must be buffered locally, and for how long? [GB, hours]

Model size / compute

- What is the edge hardware budget per device (RAM/flash/CPU/NPU, power)? [MB/GB, ops/s, W]

- Max model binary size and runtime memory you can afford on-device? [MB]

- Input characteristics: frame/sensor rate and input shape (e.g., 640×480@15fps).

- Expected model update cadence and OTA capability (staged/rollback)? [per week/month, yes/no]

You can download these questions and pass them to your technical team or refer to us for an IoT consultation. Our specialists will examine your case and provide the most suitable option with detailed explanations of the reasons behind this choice.

Below is a brief table that might help you make the right architecture choice:

| Criterion | Edge AI | Cloud AI | Hybrid AI |

|---|---|---|---|

| Critical actions at the edge; heavy compute in the cloud. | Best: ~1–50 ms on device/PLC. | ~100 ms–seconds (network hops). | Critical actions at the edge; heavy compute in cloud. |

| Bandwidth cost | Lowest (pre-filter, send summaries). | Highest (uplink raw/large batches). | Medium (selective uplink/aggregation). |

| Privacy & compliance | Strong (data stays local). | Requires strict controls/regioning. | Balanced: sensitive local, rest in cloud. |

| Offline resilience | High (works without WAN). | Low (WAN outage = blind). | Medium–High (graceful degradation). |

| Model complexity | Limited by MCU/CPU/NPU budget. | Virtually unlimited (GPU/TPU). | Split: compact at edge, large in cloud. |

| Fleet mgmt & updates | Harder (OTA, version drift). | Easier (centralized). | Mixed (staged rollout, dual channels). |

| Observability & A/B tests | Limited local telemetry. | Strong central metrics/traces. | Mixed (edge metrics + cloud logs). |

| Device energy/compute | Higher on-device draw. | Lower (centralized compute). | Medium. |

| Cost structure (TCO) | Higher capex/device mgmt. | Higher opex (compute/egress). | Balanced if filtered early. |

| Security surface | Many endpoints to harden. | Fewer device perms; big central target. | Both surfaces exist; needs zero-trust. |

| Typical use cases | Safety interlocks, on-line vision QC, vibration triage, occupancy control. | Fleet analytics, demand forecasting, NLP/copilots, cross-site anomaly hunting. | Smart buildings/factories: local loops + HQ optimization; predictive maintenance with local triage. |

| When to choose | Sub-100 ms actions, poor/expensive connectivity, strict data residency. | Complex models, cross-fleet learning, non-real-time actions, rich logs. | Need fast local decisions + centralized learning/management (the default at scale). |

Notes: Latency ranges are indicative; tune to your SLA and hardware. Hybrid is most common beyond pilots.

The Next Wave of Innovation – Theory

AIoT is the step from “connect and monitor” to “sense – decide – act.” In theory, the value comes from closing this loop automatically: devices capture context, lightweight models at the edge filter and react in milliseconds, and heavier models in the cloud learn across the fleet.

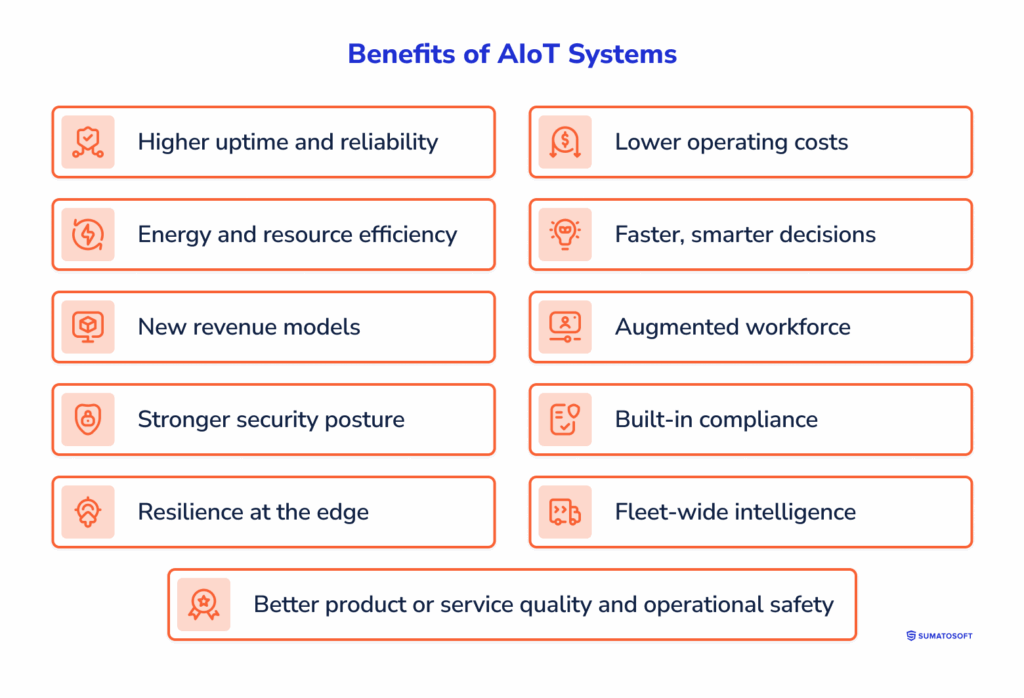

Benefits compound: higher uptime, lower OPEX and energy, better product or service quality and operational safety, faster decisions, and new service-based revenues.

Here is the full list of benefits:

- higher uptime and reliability – predict faults early, auto-adjust processes, and recover before users notice;

- lower operating costs – automate routine decisions and tuning so teams spend less time firefighting;

- energy and resource efficiency – control HVAC, pumps, and lines dynamically to cut waste without sacrificing output;

- better product or service quality and operational safety – spot defects and unsafe states at the source; prevent issues instead of inspecting them later;

- faster, smarter decisions – move from dashboards to closed loops: sense – decide – act in real time;

- new revenue models – package outcomes (uptime, accuracy) as services; sell insights, not just hardware;

- augmented workforce – give operators copilots that explain issues, suggest fixes, and capture best practices;

- stronger security posture – detect abnormal behavior on devices and networks; enforce least privilege by default;

- built-in compliance – track data lineage and access so audits become a byproduct of normal operations;

- resilience at the edge – keep critical logic local, run through connectivity outages, and sync when back online;

- fleet-wide intelligence – learn from every device, roll out better models OTA, and standardize improvements.

The Wave of Innovation – How Modern AI-Powered IoT Looks

Theory is nice, but real numbers from existing businesses must back it.

Let’s examine three real-life use cases in industries that have the greatest potential for implementing AIoT:

- manufacturing;

- city traffic optimization;

- U.S. healthcare.

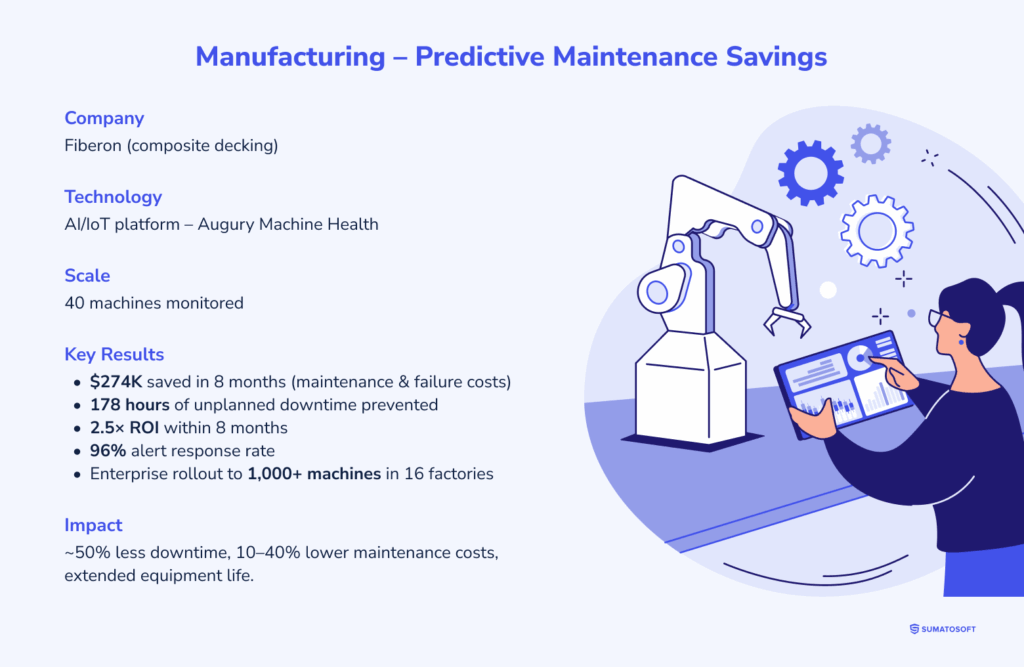

Case #1: Manufacturing – Predictive Maintenance Savings

In the manufacturing sector, AI-driven predictive maintenance has yielded significant cost and downtime savings. A 2024 case study at Fiberon (a manufacturer of composite decking) demonstrated the tangible benefits of such a system. Fiberon partnered with an AI/IoT platform (Augury Machine Health) to monitor 40 machines for early signs of equipment failure. This pilot led to:

- cost savings – over 8 months, the company avoided an estimated $274,000 in maintenance and failure costs; for example, an AI alert on one extrusion line’s melt pump allowed a pre-planned fix that saved $56,000 in repair and scrap costs;

- downtime reduction – AI-based alerts helped prevent 178 hours of unplanned downtime during the pilot; in the melt pump incident, 16 hours of downtime were avoided by addressing the issue during a scheduled shutdown;

- return on investment (ROI) – Fiberon achieved a 2.5× ROI within 8 months;

- scalability – trust in the AI system was high (96% response rate to its alerts) and the success of the pilot prompted an enterprise-wide rollout to over 1,000 machines across 16 factories.

This example shows how AI-based predictive maintenance can reduce unplanned downtime by about 50% and cut maintenance costs by 10-40%. By catching equipment anomalies early, manufacturers avoid costly breakdowns and keep production lines running smoothly, directly translating into saved money and improved operational efficiency.

Case #2: City Traffic Optimization – AI Reduces Congestion

Cities worldwide are leveraging AI to optimize traffic flows and reduce congestion. In Hangzhou, China, the city deployed Alibaba’s “City Brain” AI traffic management system. This system ingests data from cameras, sensors, and traffic signals citywide, then uses AI to dynamically adjust traffic light timing and respond to incidents in real time.

Results included:

- reduced congestion – in the pilot district (Xiaoshan), average traffic speeds increased by ~15.3% and peak-hour congestion rates dropped by 9.2%; by 2018, Hangzhou moved from being China’s 5th most congested city down to 57th in rankings, cutting its congestion index by 3.5%; commuters experienced shorter travel times (on average 3 minutes less per trip);

- improved traffic flow and safety – adaptive signal control and instant incident detection meant quicker responses to accidents and better flow; City Brain can automatically detect collisions or illegal parking and adjust nearby signals to alleviate bottlenecks; Hangzhou expanded the AI system to 1,300 intersections, contributing to smoother traffic during large events and better emergency vehicle dispatch;

- global impact – Hangzhou’s success inspired other cities; Los Angeles and Barcelona have announced AI-driven traffic light systems aiming for up to 20% congestion reduction; in Pittsburgh (USA), an adaptive AI traffic signal pilot (Surtrac) reduced vehicle travel times by ~25% and idling by over 40% in test corridors.

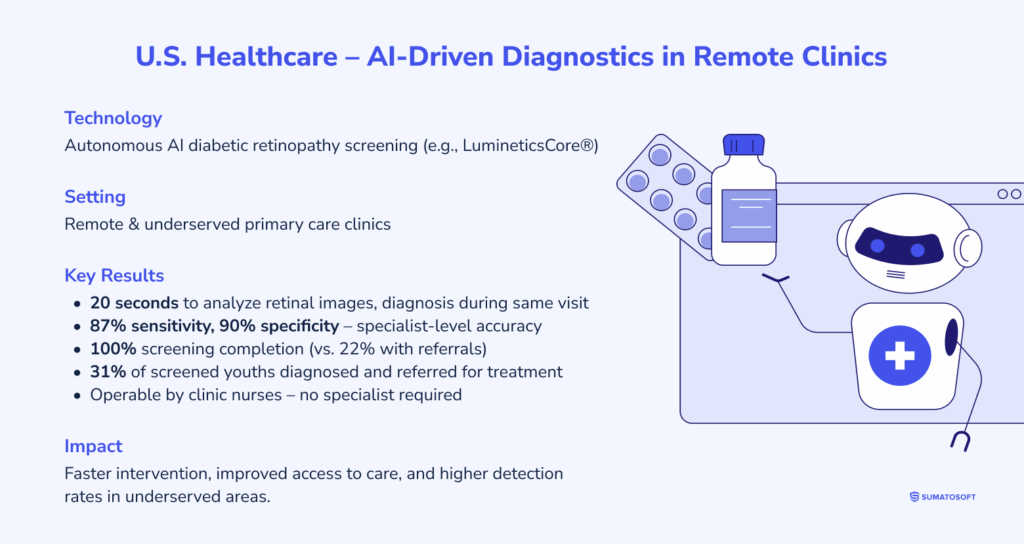

Case #3: U.S. Healthcare – AI-Driven Diagnostics in Remote Clinics

Bringing AI-driven diagnostics to remote and underserved clinics in the U.S. has increased access to care and improved diagnostic efficiency. One example is the use of an autonomous AI system for diabetic retinopathy screening in primary care.

Key points:

- on-site AI diagnostic tool – the FDA-approved system (e.g. Digital Diagnostics’ LumineticsCore®, formerly IDx-DR) can be operated by a clinic nurse to take retinal images and automatically detect disease, often in under a minute; one patient’s case saw the AI analyze retinal photos in 20 seconds and deliver a diagnosis during the same routine check-up;

- specialist-level accuracy – in a pivotal clinical trial with 900 patients, the autonomous AI achieved about 87% sensitivity and 90% specificity for the detection of diabetic retinal disease, on par with ophthalmologist-level screening;

- improved patient outcomes – AI screening dramatically increased the rate of at-risk patients being examined and treated; a 2021-2022 Johns Hopkins trial found that 100% of patients offered AI screening completed their exam on the spot, compared to only 22% in the standard referral group; 31% of the AI-tested youths were found to have signs of disease and could be referred for treatment promptly.

This case shows how AI diagnostics in remote U.S. clinics allow patients to receive faster diagnoses and treatment without the long wait or travel to specialists, leading to faster intervention, specialist-grade accuracy, and significantly higher screening completion rates.

AIoT Development Roadmap

Developing and implementing AIoT is a complex topic that we covered in other articles in our blog. For example:

Still, to understand how the process looks, we provide a brief overview of its 5 steps:

Step#1: Define measurable goals – set clear, KPI-linked targets (e.g., reduce downtime 20% in 12 months).

Step #2: Choose your AI model type – select the appropriate approach (rules, ML, DL, GenAI) based on the use case and constraints.

Step #3: Ensure data quality & governance – audit data sources, fix gaps, secure pipelines, and set access rules.

Step #4: Build a pilot project – start small with defined success metrics, cross-functional team, and fast iterations.

Step #5: Scale and integrate – expand in phases, integrate into existing systems, monitor performance, and retrain models regularly.

This basic info will be enough to understand how the process looks. For detailed information, we recommend referring to our articles. And as a bonus, you can download a checklist on launching a pilot AIoT project here.

What’s Next?

You’ve just examined the real-life cases of implementing AIoT, backed by detailed information on each case. If that’s what you were looking for, this information will be enough to understand the modern capabilities of this technology synergy.

If you plan to develop your own AIoT system, we encourage you to reach out to us at SumatoSoft. We specialize in IoT development and write something more here.

How We Can Help

At SumatoSoft, we specialize in building end-to-end custom IoT systems, including modern AIoT solutions. We design the data flow, apps, and cloud so your devices can sense, analyze, and act reliably and at scale. Our work spans IoT consulting, development, QA, and long-term support, with security and ROI built in.

What we build

- web and mobile IoT apps for monitoring, control, and automation – secure by design;

- data pipelines – device data retrieval, processing, time-series storage, analytics/visualization for actionable insights;

- remote control and dashboards tailored to fleets and facilities – device management with onboarding and OTA updates;

- edge + cloud architecture, servers/APIs, and integrations with CRM/ERP to fit your operations.

Advisory first, then build

- IoT solution consulting – opportunity discovery, product roadmap, tech stack selection, security and compliance (GDPR/HIPAA), and ROI-oriented PoCs;

- full project delivery – requirements, architecture, UI/UX, cloud and edge, QA/security, deploy, support.

Industry coverage

Healthcare IoT, retail, manufacturing, smart homes and smart cities, automotive/logistics – delivered with domain-specific patterns like RPM, predictive maintenance, and smart traffic/waste systems.

Why SumatoSoft

- ISO 27001 + GDPR/HIPAA practices; bug-fix guarantee agreed upfront;

- speed – start next day in 95% of cases, rapid MVP in ~6 months, biweekly demos;

- scale – microservices, scalable cloud, and high-volume async data handling;

- track record – 250+ custom solutions, 25+ countries, 70% senior engineers, 98% satisfaction;

- recognized by leading industry lists and agencies, awarded as a Top IoT development company by Clutch in 2022, 2023, and 2024.

- We are one of the best IoT development companies in the world.

If you’re ready to turn KPIs into outcomes – higher uptime, lower energy, fewer defects – let’s align on a roadmap and build the first closed loop that pays back.

Start in Three Steps

- Book a 30-minute AIoT readiness call.

- Share a week of sample telemetry and constraints.

- Get a free discovery session where we prepare targeted KPIs, access business opportunities for AIoT development, identify ROI, describe the work scope, and highlight realistic timelines.

If you’re serious about results, let’s turn your data into decisions and your pilot into payback. Contact us!

Let’s start

If you have any questions, email us info@sumatosoft.com