Predictive Maintenance development services

We design and implement predictive maintenance systems for small and mid-sized businesses operating real industrial equipment. Our focus is on practical PdM:

Challenges SMBs Face with PdM

Unplanned downtime and emergency failures

Equipment failures often occur without clear warning signs, leading to sudden downtime, production losses, and expensive emergency repairs. In SMB environments, even a single unexpected failure can disrupt schedules, overload maintenance teams, and directly impact revenue.

Over-maintenance driven by rigid schedules

Maintenance based strictly on time or usage intervals results in servicing equipment that is still in good condition. This approach increases labor costs, consumes spare parts prematurely, and diverts attention from assets that actually need intervention.

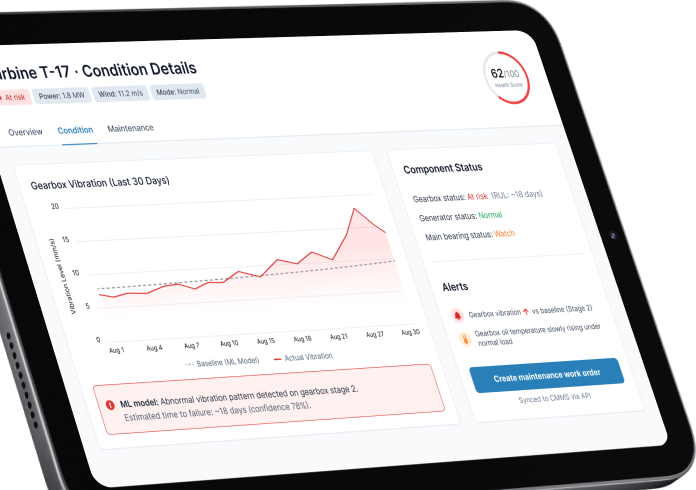

Limited visibility into actual equipment condition

Without continuous condition data, gradual degradation remains invisible. Maintenance decisions are made based on experience and assumptions rather than objective signals, increasing the risk of late detection and avoidable failures.

High noise and low trust in PdM signals

Simple threshold-based monitoring produces excessive false alarms, while advanced models often act as black boxes. When technicians do not understand or trust the signals, alerts are ignored and the system quickly loses credibility.

PdM disconnected from maintenance actions

Many PdM solutions stop at alerts and dashboards. When signals are not linked to work orders, priorities, and real maintenance actions, predictive maintenance remains informational instead of operational.

Mixed and legacy equipment reality

SMB typically operate heterogeneous environments with legacy machines and retrofit sensors. Solutions designed for standardized or “smart” equipment struggle to adapt to this reality, limiting their practical value.

Inefficient spare parts and maintenance planning

Uncertainty about when failures will occur forces companies to overstock spare parts or react too late when parts are unavailable. Both scenarios tie up capital and increase operational risk.

Subtle performance degradation goes unnoticed

Small changes in vibration, temperature, load, or efficiency often develop slowly and stay below alarm thresholds. Over time, these inefficiencies increase energy consumption, accelerate wear, and raise operating costs without obvious symptoms.

Unpredictable cost and ownership of PdM systems

SMB are cautious of PdM initiatives that become expensive to scale or require dedicated internal teams. Concerns about platform lock-in, rising subscription costs, and long-term support obligations often slow down or block adoption.

SumatoSoft predictive maintenance services

We provide two practical paths to predictive maintenance for SMB – depending on your equipment, processes, and level of control you need. Both approaches are designed to deliver value early and scale without breaking operations or budgets.

| Point | Integration of an existing PdM solution | Custom PdM development |

|---|---|---|

When this approach works |

Standard equipment types with well-known failure modes. Existing PdM platforms already support required sensors and integrations. |

Mixed, legacy, or highly specific equipment. Informal or unique maintenance processes that don’t fit standard platforms. |

Key goal

|

Fast start with minimal initial effort. |

Long-term fit with real operations and full control over evolution. |

What you get |

Faster rollout and time to first results. Predefined analytics, dashboards, and alerts. Lower entry effort. |

Architecture built around your equipment, data, and workflows. Full control over logic, thresholds, and integrations. No platform lock-in. |

Flexibility |

Limited to vendor-supported scenarios and roadmap. |

High. The system evolves together with your business. |

Data ownership |

Often constrained by platform rules and formats. |

Full ownership. Open formats and controlled data flows by design. |

Integration options |

Limited to available connectors and APIs. |

Designed specifically for your CMMS, EAM, SCADA, or internal systems. |

What to consider |

Limited customization beyond predefined scenarios. Dependency on vendor decisions and pricing. |

Requires careful MVP design and phased rollout. Value builds progressively, not instantly. |

Best fit for SMB that… |

Wants a quick start and are ready to adapt processes to the tool. |

Wants PdM to adapt to their business, not the other way around. |

Point

When this approach works

Key goal

What you get

Flexibility

Data ownership

Integration options

What to consider

Best fit for SMB that…

Integration of an existing PdM solution

Standard equipment types with well-known failure modes. Existing PdM platforms already support required sensors and integrations.

Fast start with minimal initial effort.

Faster rollout and time to first results. Predefined analytics, dashboards, and alerts. Lower entry effort.

Limited to vendor-supported scenarios and roadmap.

Often constrained by platform rules and formats.

Limited to available connectors and APIs.

Limited customization beyond predefined scenarios. Dependency on vendor decisions and pricing.

Wants a quick start and are ready to adapt processes to the tool.

Custom PdM development

Mixed, legacy, or highly specific equipment. Informal or unique maintenance processes that don’t fit standard platforms.

Long-term fit with real operations and full control over evolution.

Architecture built around your equipment, data, and workflows. Full control over logic, thresholds, and integrations. No platform lock-in.

High. The system evolves together with your business.

Full ownership. Open formats and controlled data flows by design.

Designed specifically for your CMMS, EAM, SCADA, or internal systems.

Requires careful MVP design and phased rollout. Value builds progressively, not instantly.

Wants PdM to adapt to their business, not the other way around.

Request a proposal

Receive a detailed project estimate and timeline tailored to your specific industrial equipment and IoT sensors.

Our recent works

Industries where PdM works in practice

Discrete manufacturing

- Typical assets include CNC machines, spindles, motors, bearings, gearboxes, hydraulics, and auxiliary equipment. Failures in these components often develop gradually but surface suddenly – during production, under load.

- Predictive maintenance development services in discrete manufacturing helps detect early signs of wear, imbalance, misalignment, and lubrication issues before they lead to unplanned stops. Instead of treating all machines equally, maintenance teams can prioritize the assets that actually show degradation, reducing emergency repairs and improving planning accuracy.

Food & beverage production

- Food and beverage facilities rely on pumps, motors, conveyors, mixers, refrigeration systems, and packaging lines that often operate continuously. Even short interruptions can affect throughput, product quality, and delivery schedules.

- PdM helps maintenance teams monitor asset condition in near-real time, identify abnormal behavior early, and intervene before failures disrupt production. Unlike highly regulated enterprise environments, SMB food producers typically need practical reliability improvements without heavy compliance overhead.

Industrial facilities & utilities

- This category includes compressors, pumps, generators, HVAC systems, heat exchangers, and supporting infrastructure that runs continuously or under variable load.

- Failures in these systems rarely affect a single asset – they cascade into broader operational issues. PdM helps detect rising risk early, reduce emergency call-outs, and plan maintenance windows instead of reacting to breakdowns.

Buildings & facility systems

- Commercial buildings, warehouses, and industrial sites depend on HVAC units, chillers, fans, and ventilation systems to maintain safe and usable environments.

- PdM in facility systems focuses on early detection of inefficiencies and degradation that lead to service outages, comfort issues, or excessive energy consumption. Instead of relying on fixed schedules or reactive repairs, maintenance teams gain visibility into which systems actually require attention.

Logistics & material handling (SMB scale)

- Material handling environments include conveyors, rollers, motors, gearboxes, sorters, and transfer systems where small mechanical issues can quickly lead to jams or stoppages.

Predictive maintenance helps detect abnormal loads, wear, and alignment issues before they escalate into system-wide disruptions. In logistics operations with tight timelines, preventing cascading failures is often more valuable than predicting exact failure dates.

Frequently asked questions

What are the three types of predictive maintenance?

- Condition-based monitoring – tracks physical signals like vibration or temperature.

- Anomaly detection – flags behavior that deviates from normal patterns.

- Trend-based analysis – monitors gradual degradation over time.

Most PdM systems combine these approaches.

What is a predictive maintenance technique?

A method for assessing equipment condition and detecting early failure signs, such as vibration analysis, temperature monitoring, current analysis, or anomaly detection.

What is an example of a predictive maintenance strategy?

Sensors monitor a critical asset, detect early degradation, and trigger maintenance during planned downtime – preventing an unexpected failure.

What are the 4 types of maintenance strategies?

- Reactive

- Preventive

- Predictive

- Prescriptive

Predictive maintenance balances cost, complexity, and operational value for most SMB.

Do we need clean historical data to start predictive maintenance?

No. PdM does not start with perfect datasets or long failure histories. We work with limited and fragmented data, establish a baseline from real operating conditions, and improve signal quality as data accumulates over time.

Book a free consultation

Schedule a 30-minute call with a Senior IoT Architect to discuss your current infrastructure and predictive goals.

Predictive maintenance technology stack

Embedded & firmware (sensors, edge devices)

Used for data acquisition, low-power operation, and reliable signal capture.

Sensors & hardware interfaces

Retrofit-first, non-invasive by design.

Industrial & IoT connectivity

Chosen for coexistence with OT environments and unreliable networks.

Edge & gateway software

Responsible for buffering, preprocessing, and fault tolerance.

Embedded & firmware (sensors, edge devices)

Used for data acquisition, low-power operation, and reliable signal capture.

Sensors & hardware interfaces

Retrofit-first, non-invasive by design.

Industrial & IoT connectivity

Chosen for coexistence with OT environments and unreliable networks.

Edge & gateway software

Responsible for buffering, preprocessing, and fault tolerance.

Cloud & backend infrastructure

Designed for predictable cost and gradual scaling.

Data processing & analytics

Focused on early risk detection, not AI spectacle.

APIs & integrations

Critical for operational adoption.

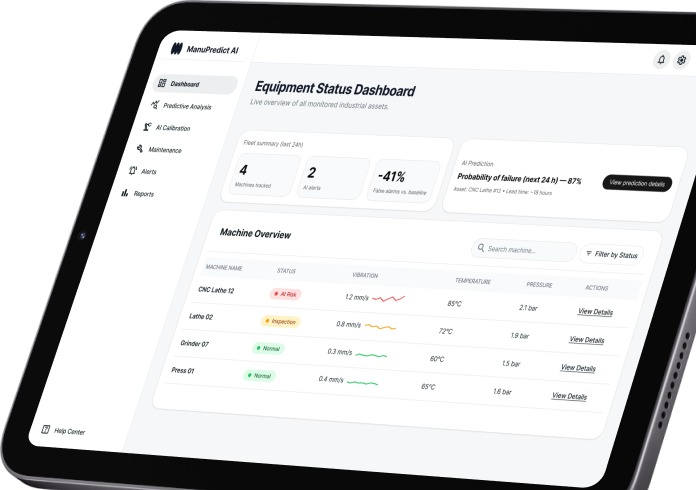

Frontend & user interfaces

Built for technicians and supervisors, not analysts.

Security & access control

Aligned with operational risk, not compliance theatre.

Deployment & operations

Designed for long-lived systems.

Cloud & backend infrastructure

Designed for predictable cost and gradual scaling.

Data processing & analytics

Focused on early risk detection, not AI spectacle.

APIs & integrations

Critical for operational adoption.

Frontend & user interfaces

Built for technicians and supervisors, not analysts.

Security & access control

Aligned with operational risk, not compliance theatre.

Deployment & operations

Designed for long-lived systems.

How we implement predictive maintenance in SMB

Predictive maintenance is introduced as a gradual operational system, not as a one-time technical rollout. The process is designed to deliver value early, remain stable under real constraints, and evolve without creating fragility or cost spikes.

We begin by aligning PdM with real maintenance work and existing constraints.

This phase includes sensor installation and calibration, baseline data collection, and initial signal tuning using real operating conditions – not ideal assumptions.

We work with limited and imperfect data, mixed equipment, and informal processes from day one. The goal is to establish a reliable baseline and ensure signals reflect actual equipment behavior, not theoretical models.

PdM always starts with a focused MVP:

- one equipment type,

- real sensors and live data,

- integration into existing maintenance workflows.

This stage is intentionally narrow. Its purpose is not technical coverage, but adoption – making sure signals are understandable, useful, and acted upon in daily work before scaling further.

The system is designed as independent modules: data collection, analytics, integrations, and interfaces.

This allows PdM to expand to new assets, signals, or sites without redesigning the core architecture.

Growth is incremental and predictable. New components are added only after the previous stage proves operational value.

PdM delivers value only when signals lead to action.

At this stage, alerts are connected to maintenance routines: work orders, priorities, and scheduling.

Technicians remain central to the process. Signal validation, feedback, and gradual tuning are built into daily use, ensuring PdM supports decisions rather than competing with experience.

PdM continues after initial rollout. We provide structured support, tuning, and updates as equipment behavior, workloads, or priorities change.

The system is designed to evolve without forced upgrades, breaking changes, or loss of control. SMB do not need a dedicated internal PdM specialist – complexity remains external and manageable.

Across custom PdM projects in mature industrial markets, the same patterns repeat:

- value appears before advanced prediction,

- integration matters more than model complexity,

- trust is built through daily use, not accuracy claims.

Operational security and data control

We design predictive maintenance so you stay in control – of your data, your workflows, and the system itself. PdM remains a manageable operational asset today and years from now, not a locked platform or a growing risk.

Data ownership by design

All operational data belongs to you. It is stored in open formats and can be exported, reused, or extended without dependency on a single vendor. This matters as the system evolves, integrations change, or PdM becomes part of a broader IT landscape.

No hidden dependencies

The system does not rely on closed logic or inaccessible pipelines. You retain visibility into how data is processed and how signals and decisions are formed – reducing long-term dependency on tools, platforms, or vendor roadmaps.

Controlled system lifecycle

Updates, extensions, and changes are handled in a predictable way. No forced upgrades, no sudden breaking changes, and no loss of control over data or workflows as the system grows.

Security aligned with operations

Protection mechanisms are designed around real operational risks:

- controlled access and role separation,

- authenticated devices and services,

- encrypted data flows,

- traceable and auditable changes.

Security supports stable operations without introducing enterprise-level overhead or complexity.

Audit your infrastructure

Get a technical assessment of your current machinery to see if you are “IoT-ready” for predictive analytics.

Why choose SumatoSoft

We design PdM systems to fit real SMB conditions. Our solutions remain practical, controllable, and valuable as operations evolve, while we keep supporting our Clients with predictive maintenance development services.

Built for real SMB constraints

PdM is designed around limited data, mixed legacy equipment, informal processes, and small teams – without requiring ideal datasets, data scientists, or organizational change.

Architecture that scales without redesign

The system is built as independent modules – data collection, analytics, integrations, interfaces – so it can start small and scale gradually without fragile dependencies or rewrites.

Early value before sophistication

We don’t start with advanced prediction claims. Value appears earlier, when degradation becomes visible and maintenance decisions improve. Advanced analytics come later, when they make sense.

Designed around people

Predictive maintenance creates value only when technicians trust and use it. When providing predictive maintenance development services, we ensure that all signals are transparent, adjustable, and validated through daily work.

Predictable ownership and long-term control

You retain control over data, logic, and integrations. Open formats and transparent pipelines prevent vendor lock-in and support long-term flexibility.

Controlled lifecycle, not forced change

No forced upgrades, no breaking changes. The system evolves in a predictable way as equipment, priorities, and scale change.

For 13+ years now we have been responsible for your projects and we are proud of it!

Awards & Recognitions

Let’s start

If you have any questions, email us info@sumatosoft.com