IoT consulting services

We’ll help you implement IoT with a systematic approach. Our IoT consulting services offer end-to-end guidance through strategy, architecture design, pilot launch, edge implementation, and analytics. We’ll make sure that your IoT is secure by design, integrated without interruptions, yields expected results and ROI, and can be trusted.

We help you to

Our IoT consulting services

IoT strategy and roadmapping

We select cases with the highest return, calculate the economics, and build a roadmap to accelerate time-to-value through case prioritization and step-by-step implementation.

Digital twin and simulation

Predictive maintenance and “what-if” simulations help reduce unplanned downtime by up to 25% and stabilize output.

Edge-to-cloud infrastructure

We reduce reporting delays by up to -60% through edge analytics and traffic optimization.

Data and analytics (AIoT and MLOps)

We detect anomalies and forecast in a data stream. The MLOps cycle accelerates model inference and reduces response time from hours to minutes.

IoT security and compliance

Secure-by-design principles, segmentation, and continuous monitoring reduce the risk of incidents and simplify audits under the ISO/IEC 62443 series.

Smart device prototyping and integration

We offer rapid device prototyping and seamless integration with legacy systems, with first results usually in 4-8 weeks without process interruption.

Unlock Your IoT Potential

Turn your IoT ideas into a connected reality with our help.

Why choose SumatoSoft for custom IoT consulting

Our key differentiators

If you choose SumatoSoft, you get an end-to-end IoT partner: from strategy and architecture design to deployment and secure IT/OT integration.

End-to-end: from strategy to edge implementation

- Strategy and ROI. We define priority cases, calculate the economics (costs/effect), create a roadmap with success metrics.

- Architecture. Edge-to-cloud reference architecture, protocol selection (MQTT/OPC UA/HTTP), network topology, data and event models.

- Devices and edge. Selection and integration of sensors and gateways, drivers, buffers for connection failures, local rules and telemetry filtering.

- Cloud or on-premises deployment. Data bus, stream processing, time series storage, API, monitoring panels; CI/CD for firmware and backend.

- Integrations. MES/SCADA/ERP/CMMS/CRM via API/ESB, synchronization of directories and events, a single asset identification model.

- Organization and support. DevOps/IoTOps processes, SLO/alerts, user training, documentation, transition to maintenance.

- Business effect. Fast pilot with a confirmed effect and predictable scaling.

Digital twins for predictive maintenance

- Asset identification. Equipment hierarchy, node criticality, sensor and failure mode map (FMEA).

- Models. Physical/semi-analytical and ML models (vibration, temperature, current analysis), residual life assessment (RUL).

- Data and quality. Time series aggregation, outlier cleanup and detection, mode metadata for model training.

- Signals and scenarios. Early warnings, failure probabilities, what-if simulations for downtime and inventory planning.

- Built-in processes. Integration with CMMS/EAM for automatic requests for repairs, SLA, spare parts selection, work order closure.

- Visualization. Asset status dashboards, degradation trends, heatmaps by workshops/lines.

- Business effect. Reduced unplanned downtime and maintenance costs, smoother release, fewer emergency work.

Get a Free Consultation

Discover how IoT can transform your business.

Industry-specific use cases

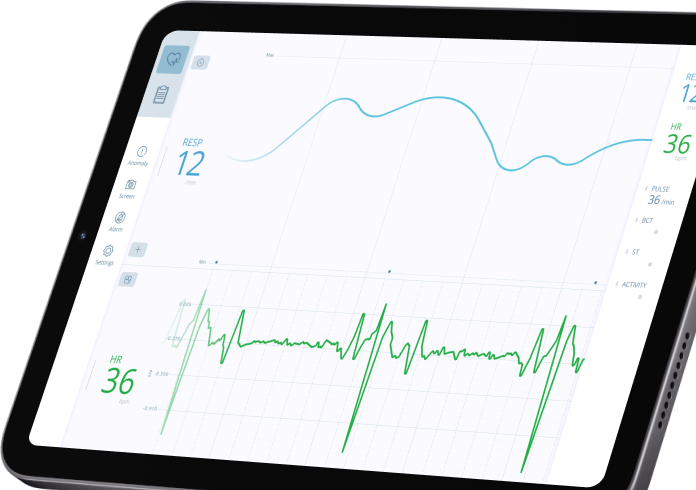

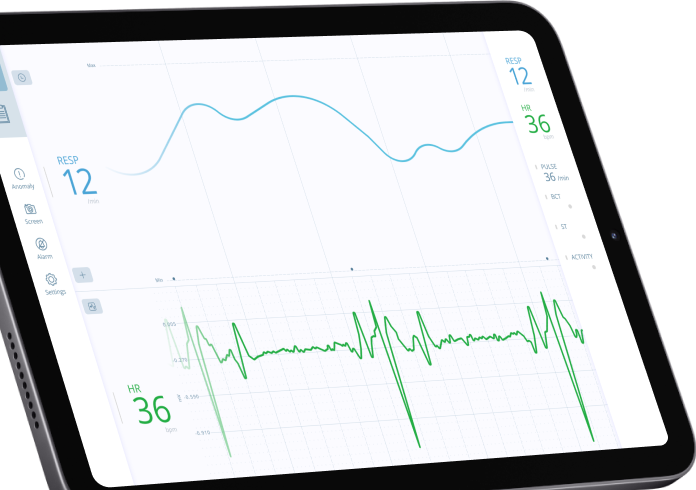

Healthcare

Combine medical sensors and mobile apps for continuous patient monitoring and rapid response.

Problem: Late detection of deviations and low treatment adherence.

Solution: Remote patient monitoring solutions and mobile apps collecting telemetry from medical sensors in real time.

Result: Prompt alerts, fewer emergency cases, better quality of care.

Manufacturing

Connect equipment and collect telemetry to predict failures and increase overall equipment effectiveness without interrupting production.

Problem: Unplanned downtime and rising maintenance costs.

Solution: Digital twin + predictive maintenance (vibration/temperature sensors, component degradation analysis).

Result: Fewer emergency shutdowns, scheduled repairs, lower overall costs.

Agriculture

Monitoring animal health and growing conditions helps to intervene in time and increases productivity.

Problem: Hidden livestock health issues, late reactions.

Solution: Monitoring animal vital signs and analytics for early intervention.

Result: Reduced mortality and costs, more stable herd productivity.

Explore our full case study on the platform for vital farm animal signs monitoring.

Transportation

Connected transport receives predictive diagnostics, route optimization, and driver safety monitoring.

Problem: Insufficient fleet visibility and ETA accuracy, high operating costs.

Solution: Telematics and sensors on transport, telemetry collection, and alerts for route and mode deviations.

Result: Predictable deliveries, less downtime and fines, optimized routing.

Smart cities

Sensors and building and infrastructure management platforms reduce energy costs and improve city services in real time.

Problem: High energy consumption and inefficient climate control in buildings.

Solution: IoT HVAC/AC control with sensors, scenarios, mobile and web apps for control.

Result: Energy savings, consistent comfort, predictable operation.

Explore our full case study on the IoT apps for controlling an air conditioning system.

Supply chain

End-to-end visibility of assets and conditions maintains OTIF and reduces write-offs.

Problem: “Blind spots” between suppliers, manufacturing, 3PL and retail; manual reconciliations, unstable ETA and SLA failures, excess or deficit of inventory.

Solution: end-to-end tracking of orders and shipments, a single control tower with predictive ETA and deviation alerts, a single data and identifier model.

Result: increased OTIF and planning accuracy, fewer manual operations and penalties, reduced inventory levels, shorter order-to-delivery cycle.

Hospitality

Connected kitchens and equipment, user-friendly interfaces for staff, and storage conditions control stabilize service quality.

Problem: Product spoilage and non-compliance with standards due to manual control of refrigeration equipment.

Solution: IoT temperature and humidity sensors for refrigerators and freezers, real-time monitoring and alerts, audit trails, integration with operating systems and POS.

Result: Fewer write-offs and labor costs, compliance with storage standards, energy savings and predictable operation.

Explore our full case study on the fridge sensors.

Education

Occupancy and environmental sensors (CO2, temperature, lighting) and panels for administrators simplify campus management and save energy.

Problem: Low classroom occupancy and unpredictable resource consumptionб no objective data on environmental quality (CO2, temperature, lighting) and room usage.

Solution: Network of occupancy and ambient sensors, energy meters, integration with schedules, dashboards for administrators and automation rules (for HVAC, light, ventilation based on actual demand).

Result: Better utilization of classroom space, stable comfort and safety, reduced energy and maintenance costs, data for campus planning.

IoT software we developed

A platform for vital farm animals signs monitoring

IoT functionality incorporation into a mobile product

Real-time blood glucose monitoring app for a healthcare technology firm

Strategic IoT challenges

| Key IoT challenges | How we approach them |

|---|---|

Security gaps Vulnerable devices, no centralized identity and encryption, no secure OTA process. |

Secure by design frameworks Threat model, network segmentation, PKI/mTLS, signed firmware and secure OTA, continuous monitoring. |

Fragmented integration Disparate IT/OT, conflicting protocols and data “islands”, difficult to interface with legacy. |

Integration roadmaps bridging IT and OT Integration map (OPC UA/MQTT/API), unified data model, phased introduction without process interruptions. |

Undefined ROI paths No prioritization of cases and metrics, unclear economics by stages, risk of a “pilot trap”. |

Outcome-based pilots with clear ROI visibility Pilots with KPI and baseline/target, a report on the effect in monetary terms/metrics and a scaling plan. |

Key IoT challenges

Security gaps

Vulnerable devices, no centralized identity and encryption, no secure OTA process.

Fragmented integration

Disparate IT/OT, conflicting protocols and data “islands”, difficult to interface with legacy.

Undefined ROI paths

No prioritization of cases and metrics, unclear economics by stages, risk of a “pilot trap”.

How we approach them

Secure by design frameworks

Threat model, network segmentation, PKI/mTLS, signed firmware and secure OTA, continuous monitoring.

Integration roadmaps bridging IT and OT

Integration map (OPC UA/MQTT/API), unified data model, phased introduction without process interruptions.

Outcome-based pilots with clear ROI visibility

Pilots with KPI and baseline/target, a report on the effect in monetary terms/metrics and a scaling plan.

Free analysis and estimation for your IoT project

Get free IoT consulting session with our team providing details about your idea

Implementation timeline

We launch a working pilot in 4 weeks and begin scaling from the 12th week.

Weeks: 1-4

Goal: to confirm value on a narrow scope.

What we do:

- Interviews and an audit to establish processes, equipment, IT/OT landscape, risks, and regulations.

- Selection of 1–2 cases with maximum impact, recording KPI and baseline.

- Technical verification to clarify or specify the Client’s requirements for sensors and gateways, protocols (MQTT/OPC UA), network, cloud or on-prem deployment.

- Telemetry collection, primary analytics or an AIoT model for mini-PoC/mini-pilot development.

Output artifacts: brief roadmap, architectural sketch, list of integrations, KPI matrix, PoC report with conclusions.

Result: a working pilot by the end of the 4th week.

Learn about the business benefits that a discovery phase brings in our whitepaper.

Weeks: 5-8

Goal: to design a scalable and secure system.

What we do:

- Detailed edge-to-cloud architecture: topology, data flows, time series storage.

- Security model with specified segmentation, device identity (PKI/mTLS), OTA updates.

- Unified data model and Integrations according to an IT/OT map.

- Identification of the best inference location (edge or cloud), model quality metrics, pipelines.

Output artifacts: architecture specification, integration plan, threat model, deployment and testing plan.

Weeks: 9–12

Goal: to confirm KPIs in production conditions and prepare for scaling.

What we do:

- Deployment of a pilot on a limited perimeter.

- Tests: functional, load, security, compatibility with legacy.

- Training and validation of the base model, drift monitoring, alerts.

- ROI transparency: comparison of actual metrics vs. baseline, effects in money/hours.

Output artifacts: pilot report (KPI/ROI), list of improvements, cut-off plan for scaling.

Result: readiness to scale in 12 weeks.

Weeks: 12+

Goal: to safely scale the solution to sites or a fleet of devices.

What we do:

- Gradual expansion of deployment automation and configuration management.

- Security strengthening through SBOM, firmware vulnerabilities, SIEM and logging, and penetration tests.

- Integrations in production with ERP and CMMS, notifications, specification of roles and operational procedures.

- CI/CD for models, canary releases, rollback policy.

Output artifacts: operational procedures, training plan, integration catalog, security reports.

Weeks: Ongoing

Goal: to maintain stability and consistently increase the effect.

What we do:

- Implementation of NOC or IoTOps for SLOs, alerting, device monitoring, scheduled OTA updates.

- Optimization through fine-tuning thresholds, expanding telemetry, new cases.

- AIoT lifecycle: retraining models, A/B testing, quality and drift control.

- Financial reporting with regular KPI/ROI reports, recommendations for the next wave.

Output artifacts: operation and ROI reports, improvement backlog, release plan.

Talk to an Expert

Connect with our IoT consultants to discuss your unique needs.

Pricing and engagement models

We offer three formats, depending on the task and its maturity level. Deadlines and budget are specified after the discovery phase. Our speed benchmark goes as follows: pilot in 4 weeks, and scaling starts from week 12.

Pilot pack

We design a short-term proof of concept to quickly confirm value on a narrow scope.

What’s included: mini-discovery, connecting one or two data sources and devices, basic edge-to-cloud flow, dashboard, security baseline, impact report, and a scaling plan.

Duration: 4–8 weeks.

Scale pack

We fully implement and integrate the pilot, turning it into a productive solution.

What’s included: industrial architecture, deployment automation, integration with ERP/MES/CMMS/SCADA, role-model access, monitoring and alerting, user training.

Duration: 3–6 months (depending on implementation waves).

Enterprise pack

We develop a custom IoT ecosystem with analytics, monitoring, and 24/7 support.

What’s included: multi-site deployment, MLOps/digital twins, data governance, SLA/24×7 support, development roadmap, and joint product backlog work.

Duration: multi-stage program (roadmap for 6–18 months).

Awards & Recognitions

Let’s start

If you have any questions, email us info@sumatosoft.com

FAQ

How do you ensure IoT endpoint security?

We design security from the bottom up and build it into the architecture at the discovery stage. Each device receives a verifiable identity: unique certificates, key issuance, rotation via public key infrastructure, and connections are encrypted with mTLS. Loading and executing code on the device is protected: secure boot, firmware signing, integrity checking before launch, and secure OTA updates with a gradual rollout and the ability to instantly roll back.

At the network level, we use segmentation, trust domain isolation, and the principle of least privilege. Strict RBAC/ABAC rules apply to users and services. Data is encrypted both in flight and at rest, and secrets are stored in KMS/HSM or a vault.

In operation, we continuously conduct an inventory of the fleet, security telemetry, behavioral analytics, correlate events in SIEM, and have proven incident response playbooks. We control vulnerabilities through SBOM, conduct regular CVE scans, and manage patching regulations.

Team processes are supported by ISO 27001/IEC 62443 practices, code review, static/dynamic analysis, and penetration tests. At the output, you get a threat model, OTA policy, access matrix, hardening checklist, test report, and response plan, so that security is a controlled contour.

Can you integrate with legacy industrial systems?

Yes, we can. We start with a map of your IT/OT landscape: we identify your PLCs and SCADA, protocols, and corporate systems, and determine the bottlenecks. Then we design an integration bridge (middleware software) without interrupting your processes: we install gateways and protocol converters at the edge, implement drivers for existing controllers, introduce buffering in case of communication failures, normalize time series and events.

We build a unified data model: tag dictionaries, binding signals to assets and lines, unification of timestamps, and data quality rules. At the enterprise level, we connect via API/ESB/iPaaS, web hooks, or message queues, so that the new solution strengthens existing processes, rather than breaks them.

We do the input in stages: first, read-only monitoring and verification, then canary inclusions, then full connection with a return plan. We confirm compatibility with bench, load, and security tests and SAT/UAT together with your teams. As a result, you get an integration map, a data contract, a cut-over or rollback plan, and operational documentation with a clear SLA for interactions.

What data ownership models do you support?

By default, all data belongs to you. We offer three basic hosting options: fully on-premises in your data center, deployment in your cloud tenant (BYO-Cloud) with keys/KMS under your control, and hybrid or multi-cloud, if you need different domains for telemetry, analytics, and archives.

Regardless of the chosen model, access is managed through a detailed matrix of roles and attributes, all actions are logged, and the principle of least privilege applies. Data is encrypted, there are clear policies for backup and retention, and for personal data, there are anonymization or pseudonymization and DLP contours.

We provide portability: export of storefronts and raw streams on request, as well as correct deletion and the “right to be forgotten” in regulatory scenarios. If the project includes AI/ML, MLOps artifacts (feature sets, models, training metadata) are also formalized by agreement: who owns the IP, how datasets are licensed, and how updates are regulated.

The result is an agreed data governance document (data processing agreement or DPA): who owns what, where and how it is stored, who has access and on what grounds, without any “grey areas”.

What’s the typical timeline for a pilot project?

An honest benchmark for a focus case without heavy hardware and complex controls is four to eight weeks. Usually, in the first two weeks, we record KPIs and a baseline, agree on an architectural sketch, connect one or two data sources, and establish a basic security contour.

By the fourth week, you already have a working proof of concept: telemetry is being collected, the first processing rules or a basic ML model for anomalies appear, there is a dashboard and alerts, so that you can see the live effect.

Then one or two iterations of rigidity are needed: stabilization of flows, integration with CMMS/ERP, performance and compatibility tests. In weeks 7–8, we conduct validation against the baseline, calculate the effect in hours and money, and compile a report and a scaling plan.

The timeline increases if specific sensors or site certification are required, access to the industrial network takes longer than usual to agree on, or integrations affect several heavy systems at once. But the key principle remains: to quickly demonstrate value on a narrow scope and not throw away the result, thus the pilot becomes the foundation for productive input.

Do you offer ongoing support and ops monitoring?

Yes, we do. We take on IoTOps in its entirety or jointly with your team. This includes 24/7 observability of devices, gateways, data flows, and integrations. We pre-configure SLOs and alerts on key metrics and provide transparent logs and reporting. Fleet management includes secure OTA updates, configuration versioning, canary rollouts, and certificate and key accounting. The security contour in operation is the correlation of events in SIEM, regular vulnerability scans, patch management, and proven response procedures. For reliability, there are redundancies, backups, regular DR scenario checks with specified RPO/RTO.

We prepare monthly and quarterly reports on KPIs, costs, and bottlenecks, and suggest measures to optimize cost and performance. If you have AIoT, we monitor the quality and drift of models, perform planned and event-driven retraining, A/B comparisons, and manage the artifact repository, so the models remain useful and do not stagnate.

The formats of cooperation are flexible: a fixed SLA, time-and-materials, or a dedicated team. In any case, you get everything you need for predictable operation and increasing the effect: support regulations, a catalog of alerts and playbooks, incident logs, and a continuous improvement plan.