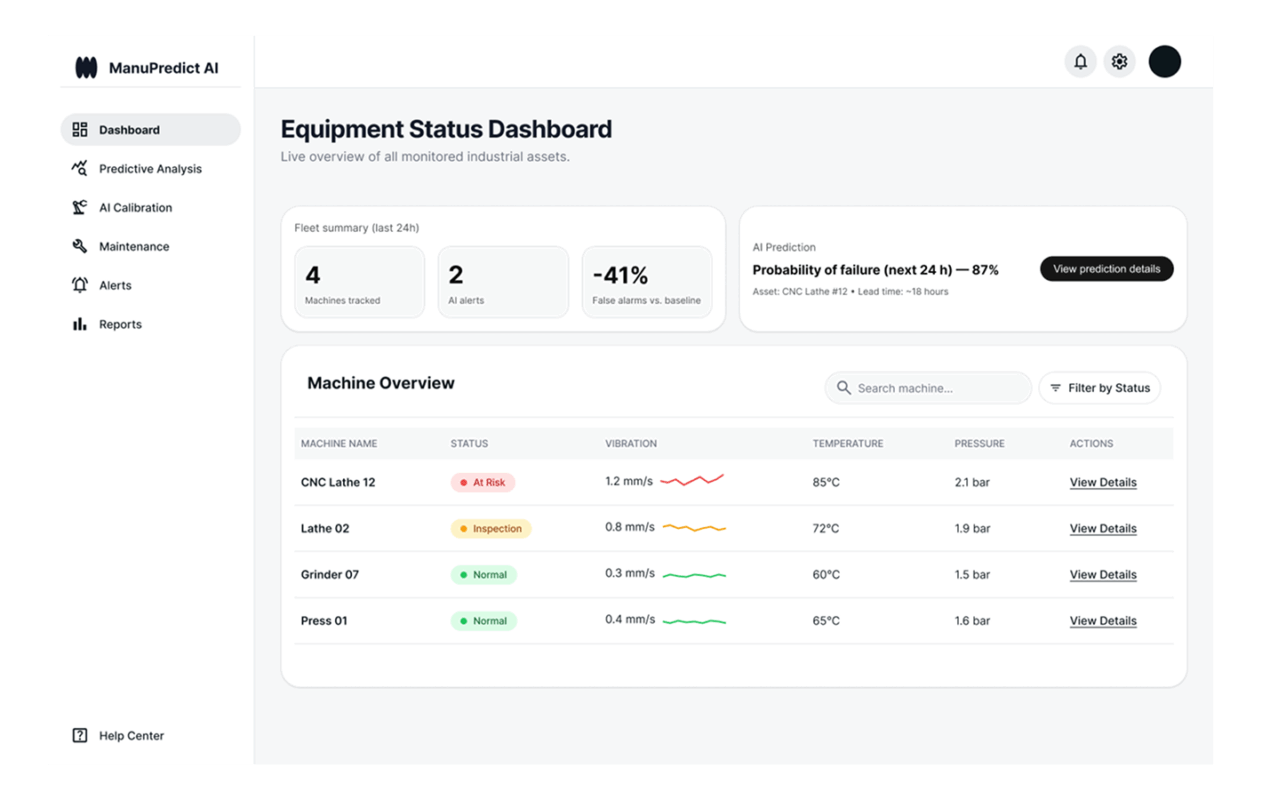

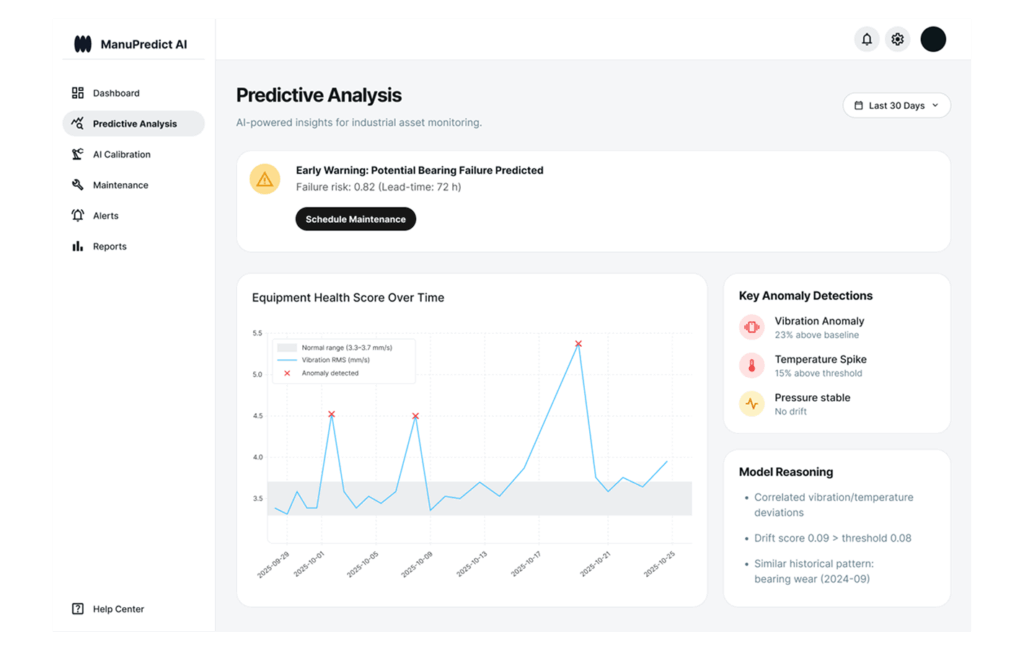

Case Study: AI-powered predictive maintenance platform for a large industrial manufacturer

An upgrade of an existing IoT system with explainable machine learning models and context-aware analytics. The solution predicts equipment failures earlier, minimizes false alarms, and integrates directly with maintenance workflows to improve production uptime.

Project details:

About the Client:

The Client is a large industrial manufacturer in Central Europe producing machinery components across multiple plants. A few years ago, we delivered an IoT foundation that streamed vibration, temperature, and pressure data from shop-floor equipment into dashboards and alerts. The system reduced unplanned downtime and enabled planned maintenance.

Location: Poland

Industry: Industrial manufacturing (machinery components)

Team size: 7 specialists (product manager, business analyst, 2 data scientists, backend engineer, frontend engineer, devops engineer)

Project duration: 6+ months

Business сhallenge

As production scaled and new machine models were introduced, prediction accuracy fell and alert noise rose. The existing system couldn’t capture complex parameter interactions (e.g., ambient temperature × workload).

The Client wanted to move from basic failure warnings to an adaptive, context-aware model that learns from new data and predicts issues earlier.

Additional requirement is to maintain stable production during development and testing.

Our solution

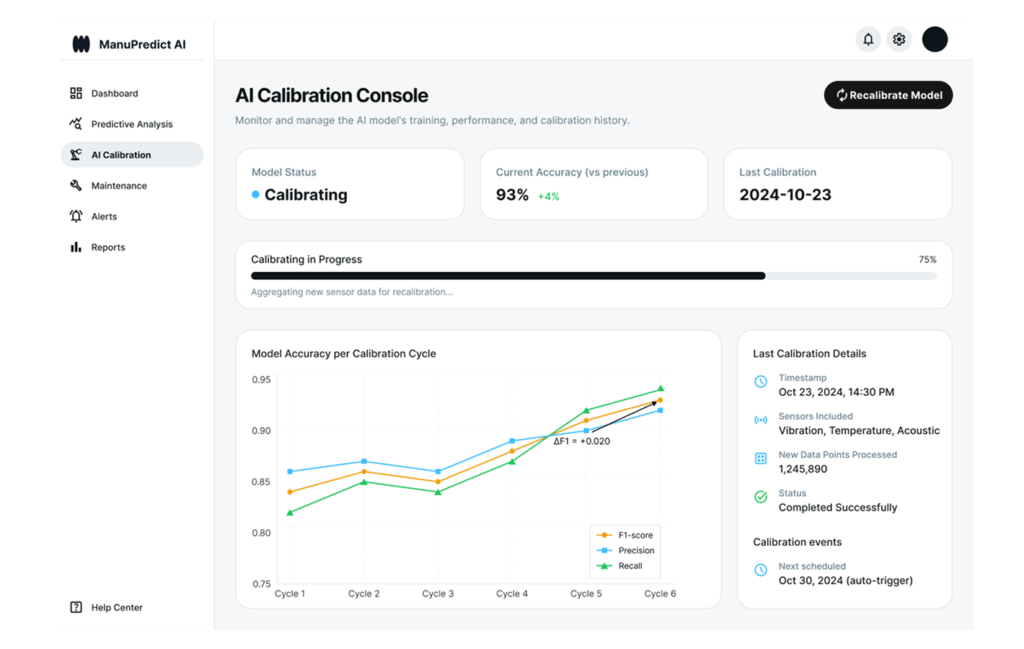

We augmented the existing IoT platform with an explainable ML layer, tied predictions to the Client’s maintenance workflow, and set up light MLOps for continuous calibration. Work happened without stopping production: we ran an 8-week pilot on selected assets, then rolled out in 6 phases, line by line.

Hybrid prediction engine

We built a hybrid prediction engine combining two complementary AI methods: a supervised model based on gradient-boosted trees (XGBoost) trained on labeled failure cases to estimate risk scores for known equipment, and an anomaly-detection module using an isolation forest and autoencoder to identify abnormal behavior in machines with limited or no failure history. Operating together, these models allow early detection of deviations while the supervised layer validates them, significantly reducing false positives and improving overall reliability.

Additional features:

- historical data – trained on multi-year (≈20 TB) vibration, temperature, and pressure records.

- adaptive learning – auto-recalibrates with each new data batch to handle new machine types.

- context analysis – blends sensor data with ambient and workload factors to cut false alerts.

- explainable AI – each alert shows key factors (e.g., vibration ↑ under high load) for the engineer’s clarity.

Business value

Before:

- The IoT system became inefficient as new equipment types were introduced.

- Prediction accuracy declined.

- Engineers received too many false alerts.

- The system captured individual signals (vibration, temperature, pressure) but didn’t model their interactions with workload and shift schedules, so early patterns were missed.

After:

- The upgraded system automatically adapts to new equipment by learning its behavior patterns and identifying risks, even without historical failure data.

- Early fault detection improved by 35%.

- False alerts fell by 40%

- Downtime dropped by nearly 50%, delivering a 2.5× ROI within months.