Exploring: 11 Positive Effects of Internet of Things in Logistics

The global logistics industry facilitates the worldwide flow of goods. It connects manufacturers, distributors, and final customers. Without extensive global logistics, I would write this article on a PC of local origin, at best. At worst, you will not be able to read this article since all underground cables that connect PCs all over the world are made of materials that were mined in different countries and transported to the manufacturers through global logistics.

The point is that logistics play a crucial role in modern society and the world economy. With the emergence of the Internet of Things development, the logistics industry experienced a shift in the way people route freight transportation and manage fleets.

In the article, we want to cover several topics:

- What is logistics

- What challenges does logistics face

- 11 positive effects of the Internet of Things on logistics

- Use cases of IoT in logistics

- Our forecasts of IoT future development

Enjoy reading!

What is logistics?

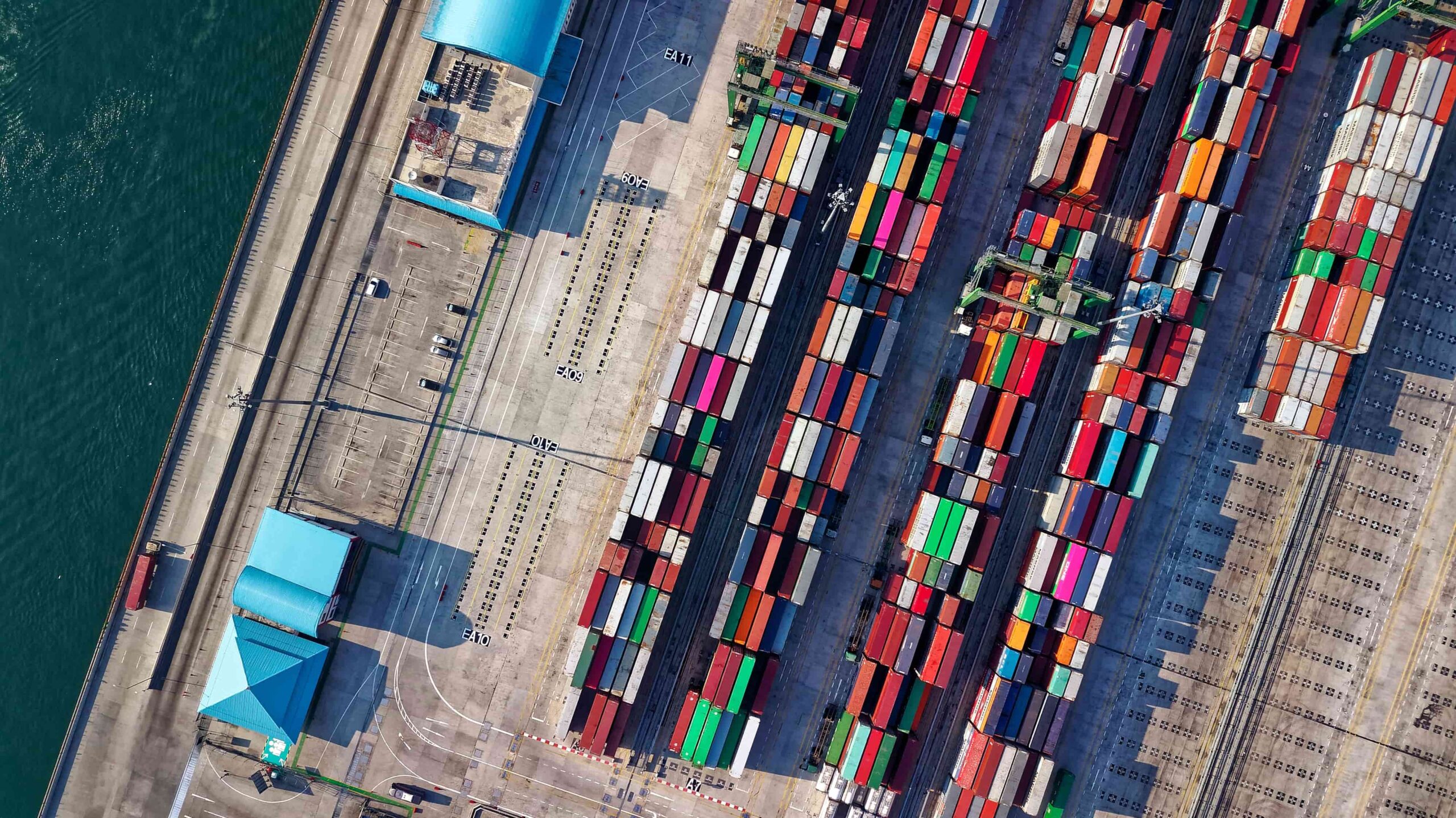

In very simple terms, global logistics comprises the processes of transferring goods or services between manufacturers, distributors, and consumers, and the managerial processes that accompany the transfer. It’s a part of the supply chain.

The logistics include 3 key operating areas :

- Management (of loading and unloading operations, planning, fleet management)

- Goods transportation and tracking (by truck, plane, trails)

- Warehousing

By leveraging the Internet of Things in logistics, companies can influence and improve these areas in many different ways. In the chapter about IoT impact, we will mark areas of influence for every benefit IoT brings. But first, let’s refer to the challenges the logistics industry has faced in recent years.

Challenges in front of Logistics

Increasing demand

The 21st century became a century of the emergence of giant marketplace platforms like Amazon, Alibaba, AliExpress, Baidu, and international technology leaders and service/products providers like Google, Apple, Facebook, Microsoft. International e-commerce volume grows up to 20% every year. The barriers that prevent companies from moving online are rapidly falling and companies get an opportunity to reach an international audience. The increase in demand and supply in the retail industry requires more precise and sophisticated logistics.

Tracking the cargo location (is especially acute for e-commerce)

Cargo loss, risks of incorrect delivery, delays in delivery, and high planning costs – these points are the result of the difficulty in tracking cargo location. Untimely reaction to the delays in the delivery from vendors to the producer can lead to the halt of the manufacturing process. The absence of information about goods geolocation and estimated time of delivery can lead to the customer’s loss in the e-commerce sector.

Unforeseen breakdowns of transport and its failure

Unplanned downtown, unforeseen breakdowns of transport, fines for non-delivery because a truck broke down – issues logistics operators have to deal with. To address that issue, equipment and fleet get maintained whether it needs it or not. This approach to maintenance is labor-intensive and ineffective since the failure can occur between planned fleet checks. So logistics need more accurate and robust methods for fleet maintenance.

Violation of the conditions of storage and transportation of products

Some goods become spoiled during transportation because they were stored at an unsafe temperature or humidity level. Some sensitive equipment can arrive with malfunctions because it was titled during transit and nobody noticed. The financial and time losses can be enormous in cases of the transportation of high-cost equipment or a huge amount of perishable cargo.

New technologies require new equipment, new processes, and new skills

Implementing any technology requires additional equipment. By adopting IoT technology, a company needs to buy several thousand sensors and actuators, hundreds of gateways, clipboards, and servers for analytic tools like Big Data and Machine learning. The Internet of Things in logistics requires employees who will analyze the data, maintain an IoT fleet, release security patches and control the security of the IoT ecosystem.

Although the IoT device cost decreases year by year and there is a huge number of reliable IoT software providers, the cost of implementing IoT technology remains a huge challenge for logistics operators.

Uncontrolled negative climate effect

Ground transport is the main source of CO2 emissions that trap heat from the sun on Earth and lead to gradual climate change. Some tankers carry cargo that is harmful to the environment like oil and oil products. There is a practice of washing tankers’ decks in the ocean. Only because of that between 8 and 20 million barrels of oil are dumped into the sea annually. Sometimes tankers accidentally spill oil into the seas leading to environmental degradation and the death of animals and even species. These issues are the main points of concern in the 21st century.

Inventory control

Companies use warehouse management systems and barcode scanning to control the movement of goods within and outside the store. These systems use simplified automatic technologies to manage the warehouse. However, these systems are not fully automated and require human participation. As a result, logistics operators deal with stock shortage, overstocks, theft, inaccurate goods location in a system, and other costly problems.

The Internet of Things in logistics is capable of addressing these issues and brings enormous benefits to logistics operators. Let’s see how.

How The Internet of Things Improves Transportation and Logistics

A few decades ago you needed weeks to receive a letter from another country. Today you can get an email in 10 seconds after it was sent from any part of the world.

A few decades ago you spent several hours in shops to buy goods and clothes. Today you can order them via the Internet for a few minutes.

The search for service providers or partners could take months. Today you can browse the Internet and find a necessary contact during the day.

New opportunities led to new requirements. Everything should be faster, and logistics is not an exception. Nowadays, logistics operators deal with requests when they need to ship cargo overnight or the next day. They need to work fast and provide great accuracy.

That is the reason why logistics and transportation were among the early adopters of IoT technology. And that technology has had a substantial impact on many aspects of logistics.

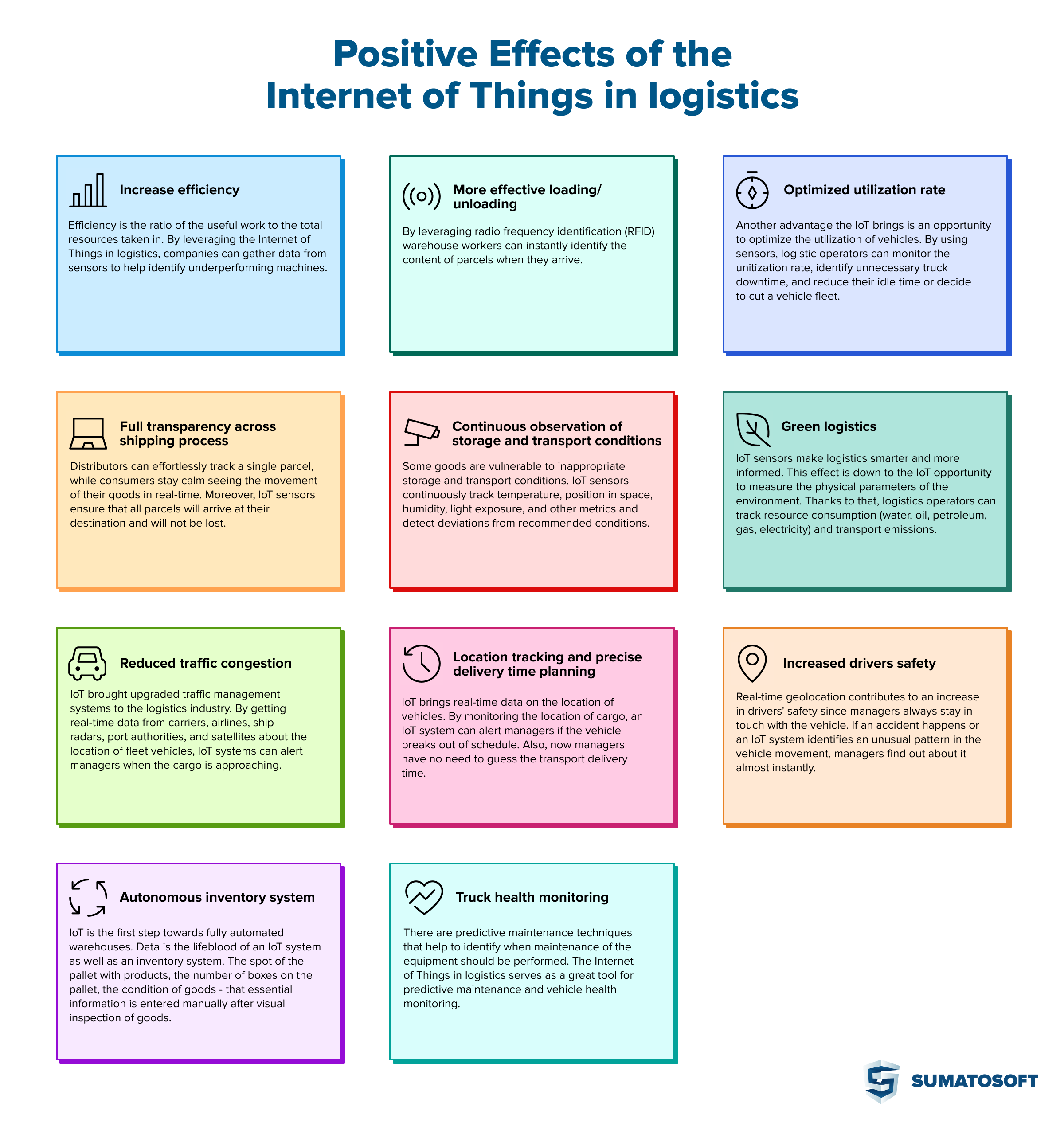

11 Impacts of the Internet of Things on Logistics

#1 Impact: Increase efficiency

Efficiency is the ratio of the useful work to the total resources taken in. By leveraging the Internet of Things in logistics, companies can gather data from sensors to help identify underperforming machines. They can connect different assets and synchronize their work to minimize idle time, provide continuous manufacturing thanks to the precise delivery, reduce the number of management components twice, increase picking performance in warehouses, and much more.

That allows for to reduction of operational costs and leads to a higher level of operational efficiency.

Influence areas:

- Management

- Goods transportation

- Warehousing

#2 Impact: Reduced traffic congestion

The Internet of Things in logistics brought upgraded traffic management systems to the logistics industry. By getting real-time data from carriers, airlines, ship radars, port authorities, and satellites about the location of fleet vehicles, IoT systems can alert managers when the cargo is approaching. Thus they have enough time to prepare staff, equipment, and place to accept/ship the goods. Moreover, logistics operators can orchestrate the movement of ships, railcars, and trucks based on up-to-date information on traffic speed, congestion, number of approaching vehicles, etc.

The global effect that refers to all drivers on the roads is the reduction of traffic congestion thanks to improved GPS-based smart routing of trucks.

Influence areas:

- Management

- Goods transportation

#3 Impact: More effective loading/unloading

By leveraging radio frequency identification (RFID) warehouse workers can instantly identify the content of parcels when they arrive. Moreover, warehouse managers can see assets and their location in real-time, which allows them to orchestrate pallet loaders more effectively. Moreover, RFID technology unlocks fast invoicing and more accurate reports which, in turn, results in speeding up the turnover of freight and faster check-out process.

Influence areas:

- Management

- Warehousing

#4 Impact: Location tracking and precise delivery time planning

IoT brings real-time data on the location of vehicles. This positive effect of the Internet of Things in logistics produces two positive effects. The first effect is that all parties get an accurate time of delivery. By monitoring the location of cargo, an IoT system can alert managers if the vehicle breaks out of schedule – thus managers are always kept in the loop. The second positive effect is information-based planning since managers have no need to guess the transport delivery time – they know it for sure and can even get a reminder an hour before the vehicle arrives.

Influence areas:

- Management

- Goods transportation

#5 Impact: Optimized utilization rate

Another advantage the Internet of Things in logistics brings is an opportunity to optimize the utilization of vehicles. By using sensors, logistic operators can monitor the unitization rate, identify unnecessary truck downtime, reduce their idle time or decide to cut a vehicle fleet.

Influence areas:

- Management

#6 Impact: Increased drivers safety

Real-time geolocation contributes to an increase in drivers’ safety since managers always stay in touch with the vehicle. If an accident happens or an IoT system identifies an unusual pattern in the vehicle movement, managers find out about it almost instantly and get an option to take necessary action timely.

Influence areas:

- Management

- Goods transportation

#7 Impact: Full transparency across the shipping process

We embrace the Internet of Things in logistics as a key to transparency since it provides real-time data about parcel or cargo shipping status. Distributors can effortlessly track a single parcel, while consumers stay calm seeing the movement of their goods in real-time. Moreover, IoT sensors ensure that all parcels will arrive at their destination and will not be lost.

Influence areas:

- Goods transportation

#8 Impact: Autonomous inventory system

The Internet of Things is the first step toward fully automated warehouses. Data is the lifeblood of an IoT system as well as an inventory system. The spot of the pallet with products, the number of boxes on the pallet, the condition of goods – that essential information is entered manually after visual inspection of goods. However, there are options for how to replace manual labor. Inbound gateways can scan RFID tags to read the information about goods on the pallet. Video cameras can detect damage during pallet arrival, and proximity sensors help to analyze inventory positions and stock levels.

Influence areas:

- Warehousing

#9 Impact: Continuous observation of storage and transport conditions

Some goods are vulnerable to inappropriate storage and transport conditions. Examples of such goods are sensitive equipment, perishable goods, and pharmaceutical products. IoT sensors continuously track temperature, position in space, humidity, light exposure, and other metrics and detect deviations from recommended conditions.

Influence areas:

- Goods transportation

- Warehousing

#10 Impact: Truck health monitoring

There are predictive maintenance techniques that help to identify when maintenance of the equipment should be performed. The Internet of Things in logistics serves as a great tool for predictive maintenance and vehicle health monitoring. Various sensors like infrared, corrosion detection sensors, vibration sensors, oil level detectors, and other types are placed on different vehicle parts to perform real-time health inspections and identify the level of physical stress and machine wear. It helps to detect signs of defects before the machine failure occurs and schedule a maintenance session to fix it. Predictive maintenance reduces the risks of unexpected breakdowns and failure on the route, dramatically reducing maintenance costs.

Influence areas:

- Goods transportation

#11 Impact: Green logistics

IoT sensors make logistics smarter and more informed. This effect is down to the IoT opportunity to measure the physical parameters of the environment. Thanks to that, logistics operators can track resource consumption (water, oil, petroleum, gas, electricity) and transport emissions. That, in turn, has a direct bearing on environmental sustainability and allows companies to identify resource leaks and cut the consumption level of the fleet as well as reduce the level of environmental emissions.

Influence areas:

- Goods transportation

IoT in Logistics: Use Cases

DHL SmartSensors

DHL’s SmartSensors use IoT technology to track and monitor the condition of sensitive goods during transportation, such as pharmaceuticals and food. The sensors provide real-time data on temperature, humidity, and other environmental conditions, allowing logistics companies to ensure that products are transported under the appropriate conditions.

Maersk’s Remote Container Management

Maersk, the world’s largest shipping container company, uses IoT technology to remotely monitor the condition of shipping containers. The company’s Remote Container Management system provides real-time data on factors such as temperature, humidity, and location, allowing logistics companies to ensure that products are transported under the appropriate conditions.

Amazon’s Kiva Robots

Amazon uses IoT-enabled Kiva robots in its warehouses to automate and optimize the fulfillment process. The robots use sensors and analytics to navigate through the warehouse and transport products to workers, reducing the time and effort required to fulfill orders.

IoT in logistics: Our Forecasts

IoT has experienced a huge boost in growth in recent years because of the COVID-19 pandemic and the increased demand for contactless operations. However, there is still one big challenge evangelists of the Internet of Things in logistics will have to solve: security. Data privacy within an IoT system is low, and connections are not protected from unauthorized access outside the system. But we believe that people will manage to address that issue.

Speaking about trends, we want to highlight that the future of the Internet of Things in logistics is directly related to the development of other technologies.

The Internet of Things and Other Technologies

IoT and Big Data

Data is the lifeblood of IoT architecture. To get the maximum result from it we need complex analytic techniques and methods that are designed to operate with a great volume of unstructured and unclassified data. Big Data is supposed to provide smart analytics, and the collaboration between the Internet of Things and Big Data will continue to strengthen.

IoT and Machine learning

Smart voice assistance, dynamic route optimization, enhanced risk management, predictive maintenance – all these benefits become possible thanks to machine learning. Owners and specialists believe that technology will be able to change the logistics industry and make it more robust and efficient. We believe that too.

IoT and Robotic automation

Once upon a time, self-driving drones and cars were the stuff of science fiction. Today they are a reality we deal with. The automotive industry grows, robot technology becomes cheaper, and more and more companies build new machines that can unload and load goods, manage warehouses, deliver small parcels by air, or even transport goods to the destination without a driver behind the wheel. It becomes easier to integrate these technologies into businesses and that trend will continue to grow.

IoT and 5g

The Internet of Things in logistics only exists when all gadgets are connected through the Internet. The better the connectivity the stronger IoT is. That is why the development of IoT and 5g complement one another because the needs of IoT influence the spread of 5g. And vice versa: the wider the 5g network is, the more complex and fast IoT systems companies can build. 5g is faster, provides lower latency, and has more capacity compared to 4g technology. All these factors are crucial for IoT systems.

IoT and Blockchain

Theoretically, the collaboration between these two technologies could solve the security issue in logistics. Blockchain enables participants to access IoT data securely because every transaction and access point is verified by a private blockchain network. However, the mass adoption of this collaboration is still to come.

Every IoT System is Build By a Reliable Software Provider

SumatoSoft is a software development company that builds complex logistics & transportation software solutions and large-scale enterprise applications. Our specialists have over 9 years of experience in creating custom solutions. In our portfolio, there are over 150 successfully developed software products for companies in 29 countries all over the world. We help to improve warehouse management, transportation management, inventory management, and much more.

Contact us and get a free quote today!

Let’s start

If you have any questions, email us info@sumatosoft.com