Role of Internet of Things in the Oil and Gas Energy Sector

Internet of Things technologies represent emerging innovations that revolutionize cross-sector businesses. The innovation enables firms to improve their operations by automating key tasks and creating ongoing forms of data collection and analysis.

Current research in the oil and gas energy sector indicates that IoT technologies provide several key benefits to organizations that integrate them into their operations. The findings describe the application’s role in analyzing data, monitoring ongoing processes, and assisting field-based leaders in their risk management strategies as specific functions that benefit the energy sector. This article examines how these trends benefit different companies in the field.

Internet of Things: Conceptual Definition

Internet of Things (IoT) technologies represent advanced networks that rely on automated systems of data delivery and exchange.

Yasar and Gillis identified the core elements that support an implemented IoT application.1. The author noted that optimized networks rely on a host data center to manage their operations, sensors to control the data, and ports that connect data between a client and a host. Yasa and Gillis defined “smart” household appliances and patient medical wearable devices as common IoT applications.1.

Ahmetoglu et al., however, also contended that companies in other fields manufacture advanced and practical IoT models that simplify their data management processes.2.

Shiklo referenced seismic exploration sensors as devices in the oil and gas energy sector as applications that enhance the work of field-based organizations.3 The applied technologies provide companies such as Shell with automated real-time data flows that examine the physical features of potential underground dig sites.

Emerging IoT technologies in different fields achieve several critical goals that enhance the quality of an organization’s analysis, planning, and performance.

Ahmetoglu et al. contended that enterprises develop competitive advantages by creating practical technology management strategies that integrate IoT capabilities into specific areas of their operation.2.

Akpan noted that firms in the petroleum industry benefit from the innovation’s data gathering, monitoring, and system maintenance processes.4.

The selected tasks represent ongoing areas of a company’s operations that can be enhanced through the application of strategically placed IoT sensors. Storts described how low-orbit Earth satellites use automated data capture processes to benefit planning systems in different petroleum companies.5. The author noted that the satellites provide a reliable form of information gathering and delivery that supports a firm’s analysis procedures. The value of the data captured by these applications includes its reliability, timeliness, and ability to be applied to different areas of organizational planning.

Current research also describes the limitations and security risks that tend to impact IoT applications in cross-sector organizations. Taherdoost argued that automated data management systems tend to create two broader challenges in various enterprises.6.

First, the applications require organizational leaders to identify the specific role that IoT systems will provide in their firms’ operations.

Secondly, Taherdoost defined the networks’ automation and reliance on machine-based data delivery processes as a factor that contributes to their security vulnerabilities.6

Sharma contended that petroleum companies need to adopt IoT integration strategies that correspond with their strategic objectives.7. The author also identified internet coverage gaps in remote areas as variables that often create technical challenges for firms as they use IoT-based applications to generate and gather data. Sharma et al. noted that field-related enterprises need to carefully manage these threats due to their potential for destabilizing their operations and their broader industry. 8. Akpan referenced cybersecurity concerns as factors that can negatively impact the petroleum energy field’s emerging IoT strategies.4.

The combined themes indicate that while the technologies potentially support an oil and gas company’s planning and business processes, sector leaders need to develop strategic practices that integrate the innovations into key areas of their operations and anticipate their potential limitations and risks.

Purpose Statement

This article examines the impact that Internet of Things (IoT) applications have on the oil and gas sector. The analysis relies on a combination of industry-related reports and peer-reviewed journal articles to address the following themes.

- The article first describes the broader-level IoT-related practices that field-based organizations follow as they integrate the technology into their operations.

- Secondly, the discussions reference the specific applications that facilitate these processes.

- A third finding identifies the potential benefits and risks that impact petroleum sector companies as they rely on IoT technologies.

- The article’s fourth theme defines the strategic and business-level value that the innovations generate for petroleum firms.

- Finally, the aggregate discussions analyze the best practices that can improve an organization’s approach to using IoT systems. The collective findings contribute to scholarly understandings of these themes and provide practical solutions to field-based companies.

Broader-Level Industry Trends

The oil and gas energy field represents a critical industry in the global market. Kumar noted that the industry generates approximately $43 billion annually.9 The same author observed that sector-based companies rely on IoT applications to manage the risks that impact their firms. According to Halsey et al., the sector faces several significant risks as it operates in an evolving global business environment.10 The authors cited the challenges associated with resource limitations, regulatory mandates, energy site extraction location processes, and technological changes as notable examples. A report published by Dziuba referenced IoT applications as digital innovations that help sector-based organizations manage these risks.11 The technology’s reliance on automated data flows, real-time information processing, and application versatility strengthens a company’s ability to anticipate and control recurrent problems in the field.

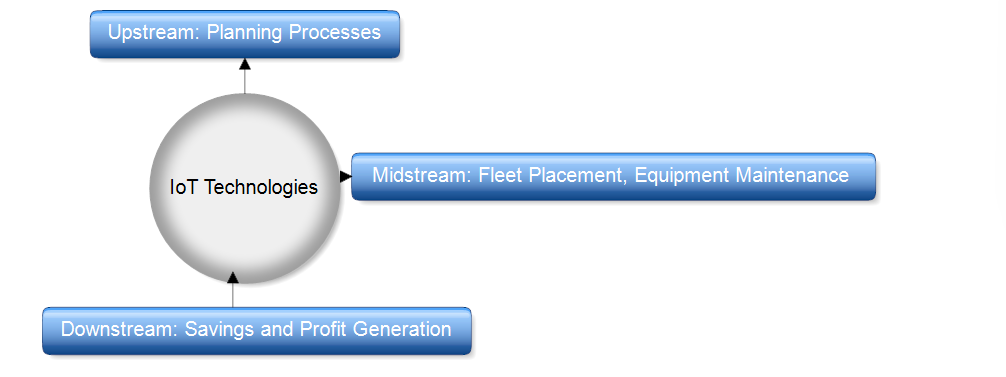

Analysts define three broader trends that impact an organization’s approach to IoT use and management.

Shiklo described these processes as upstream, midstream, and downstream-related functions.3

According to the author, petroleum companies rely on IoT technologies to upstream their operations as they develop strategic plans that achieve three primary outcomes. The selected applications improve their approaches to site selection, drilling, and using downtime in ways that improve their operations.

Storts referenced satellite-based sensors as IoT applications that generate seismic wave activity and predict the potential value of a selected drill site.5 The latter practice helps companies limit their risks while locating a region for gas and oil extraction, enhance their profitability by locating productive energy sources, and adhere to external compliance mandates.

Secondly, Shiklo defined IoT technologies as innovations that enhance an enterprise’s midstream-related processes.3 The latter term describes the planning steps that companies utilize as they place their fleets in desired locations and repair their equipment.

Dziuba cited IoT machine-to-human and machine-to-machine analytical processes as functions that help corporate leaders in petroleum companies identify an optimal site for their ground crews and fleets.11 The same author noted that firms monitor their equipment’s quality and need for repair by using IoT-based sensors to monitor these variables. According to a report published by Sierra Wireless, the Oklahoma Natural Gas company uses IoT-based sensors to monitor their pipelines and auxiliary equipment in the field.12 The selected practice helps the organization reduce its spending on major repairs and maintain its compliance with its industry’s regulatory mandates.

The third value-adding benefit that IoT systems deliver to petroleum companies includes their role in increasing an enterprise’s profitability. Akpan argued that energy firms often achieve mixed effects as they apply IoT technologies to their processes.4

At one level, the systems promote ROI-based savings by reducing avoidable expenses. IoT applications, for example, identify weaknesses in a company’s supply chain practices, worker safety risks, and environmental disasters.13 The collective outcomes enhance a firm’s risk management strategies and strengthen its ability to anticipate potential problems. Shiklo defined these processes as examples of an IoT system’s downstream-related capabilities.3.

A report published by Biz Intellia, however, also indicated that the technology can enhance a firm’s profitability.14. Dziuba estimated that a company’s optimal use of IoT technologies can increase its earnings by 30-50%.11.

Enterprises achieve this latter outcome by using the applications to locate viable digging or extraction sites, analyzing field-based conditions that could impact these processes, and studying longer-term geological patterns associated with the region. The data emerging from IoT systems thus creates valuable forms of business intelligence that can help companies manage risks and enhance their profits as they select specific extraction sites. Figure 1 summarizes the broader forms of value that IoT systems create within the industry.

Figure 1: IoT Technology’s Broader Impact on the Gas and Oil Industry

Specific Applications

Internet of Things-related technologies can be defined in terms of their increasing diversity.

Allioui and Mourdi contended that cross-sector organizations effectively leverage this technology by selecting specific applications that benefit their operations.15. Daws estimated that by 2028, the oil and gas energy sector will have installed approximately 7.8 million IoT-based satellite and wireless systems.16. The latter finding illustrates two critical themes related to the technology’s value in the sector.

- First, industry-based companies will continue to invest in the broader application as they seek to manage their risks and achieve desired strategic goals.

- Secondly, corporate decision makers select specific applications to achieve these goals. Companies achieve both outcomes by identifying how existing and emerging IoT technology will enhance their operations.

Petroleum firms rely on a variety of IoT applications as they strengthen their business models.

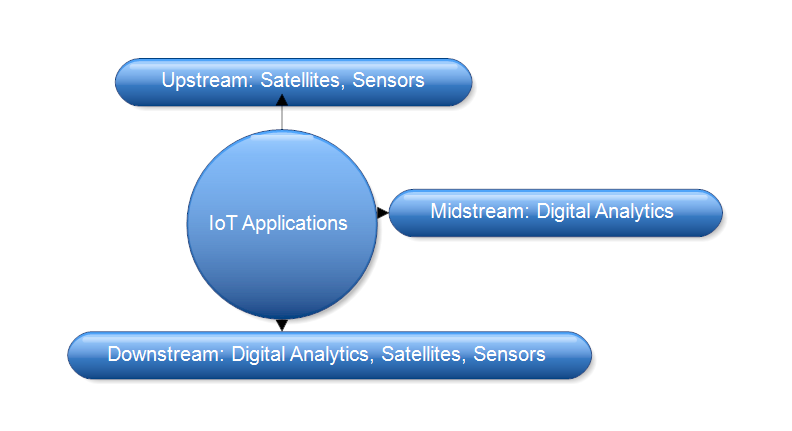

Sharma identified the three broader practices of using the technologies in upstream, midstream, and downstream operations as methodologies that enhance a competing firm’s capabilities.7.

The identified functions strengthen a firm’s operations through strategic planning, asset management, and business-level activities. A report published by Deloitte also described a fourth trend that involves the development of underlying infrastructure as a broader technological management strategy.17 According to the analysis, the latter methodology constructs sustainable technological architecture that supports a company’s diversified functions in developing and enhancing its core IoT processing capabilities. The primary applications used in this latter strategy include the use of sensors, asset monitoring systems, and digital twins. The latter applications enable companies to evaluate their existing or emerging equipment resiliency under severe weather conditions.

Upstream capabilities

Sector-based companies enhance their planning-based upstream capabilities by relying on various IoT applications. Storts identified low-orbit satellites (LOS) as advanced systems that enable oil companies to monitor seismic activity in targeted extraction sites.5. The data exchanged between the LOS and corporate databases enables leaders to determine if a proposed location would provide a stable source of extracted fuel. Lee noted that remote-based monitoring systems deliver continuous data streams that evaluate the quality of pipelines, rigs, and other essential equipment.18. The information enhances a company’s upstream processes by converting system and crew downtime into productive ongoing monitoring activities. Tayliyev indicated that companies interconnect the data they receive from various IoT and human-based monitoring procedures into their digital analytics strategies.19. The latter application can be viewed as a fusion between human and machine intelligence that strengthens an organization’s upstream-based planning activities.

Midstream capabilities

Sector-based firms use IoT applications as they engage in midstream-based planning. Shiklo defined these processes as an organization’s role in enhancing their crews’ and operational equipment’s capabilities.3. The activities of monitoring and repairing pipelines, upgrading digital applications, and rerouting personnel to different sites represent notable examples.

Downstream capabilities

A report published by Sierra Wireless indicated that Pason monitoring platforms provide SCADA-based capabilities as they deliver real-time data that analyzes the condition of rigging equipment, auxiliary applications, and pipelines.12. The digital information that energy companies receive through IoT applications evaluates their infrastructure’s current and predictive conditions.

Based on this information, corporate leaders cultivate strategic plans that help them identify and manage potential risk factors. Dziuba contended that similar applications can enhance a firm’s ability to generate savings-based ROIs and develop profitable business solutions.11 The latter theme indicates that satellites, sensors, and digital monitoring programs contribute to an enterprise’s upstream-related planning processes. The same author, however, also noted that a small percentage of firms rely on IoT systems to guide their business and market performance strategies. Figure 2 summarizes the relationship between various IoT applications and their impact on specific areas of an energy company’s operations.

Figure 2: The Role of IoT Technology in Different Corporate Planning Phases

IoT Technology and Value Creation in the Energy Sector

As energy sector firms operate in their industry, they face a diverse range of challenges. Halsey et al. contended that many of these issues can be defined as industry-level concerns. Competing organizations face the same resource-related gaps that impact their ability to maintain a healthy profit margin.10.

Energy sector firms also balance their enterprise’s business needs with their dimensions of corporate ethics and regulatory compliance.

Finally, the enterprises assume considerable financial and operational risks as they place their crews, equipment, and pipelines in selected geographical locations. Current research indicates that the value created by IoT technologies includes their role in enhancing a company’s risk management, compliance, and business planning activities.

Energy sector firms rely on IoT applications to enhance their risk management strategies. The primary challenges impacting companies include their ability to predict valuable drilling and extraction sites, maintain their crews and equipment, and predict changes in their operational or market environment that could impact their current strategies.

A report published by Deloitte indicated that seismic sensors help companies evaluate the conditions associated with various proposed extraction sites.17. The findings also noted that IoT-based sensors allow firms to carefully monitor their equipment’s condition. Lee cited the latter technologies as systems that perform routine maintenance.18.

The collective findings indicate that diversified IoT applications help firms manage and mitigate the risks associated with site selection and equipment breakdown or failure. According to Dziuba, the same applications enable companies to comply with their industry’s regulations.11. Integrated IoT systems, for example, predict structural weaknesses in pipelines and equipment that could result in ecological disasters. A report published by the Digi International group described automated analytics as platforms that produce savings and profitability in organizations.20. The latter applications identify solutions to site selection, logistics, and operations management that could help firms create a competitive advantage.

Benefits & Risks

Current research describes the benefits and risks that could impact an energy company’s reliance on IoT technology.

- First, analysts define the concept’s benefits as a holistic set of potential outcomes. Automated systems improve an enterprise’s quality of business intelligence The latter feature helps companies locate solutions for their upstream, midstream, and downstream planning processes that achieve multilevel benefits.

- The applications also enhance an enterprise’s compliance strategies.

- IoT technology’s primary risks include its operational and security challenges. Corporate leaders can anticipate the first set of threats by developing detailed planning strategies that define how specific IoT applications will contribute to specific business-level goals. Firms can mitigate and manage the comprehensive digital risks that tend to impact IoT systems by developing high-level cybersecurity strategies.

Summary: Best Practices Using IoT Technologies

The preceding report identified the following practices that help energy sector companies maximize their use of IoT technologies.

- First, firms should recognize the strategic importance of integrating automated data management systems in different areas of their operations.

- Secondly, corporate leaders should develop detailed plans that identify how specific applications will generate specific outcomes.

- Finally, the analysis indicated that optimized IoT-based technology management strategies achieve multilevel goals in an organization. Key examples include the innovation’s role in enhancing upstream, midstream, and downstream-level planning activities.

We at SumatoSoft develop custom IoT applications for any business challenges.

SumatoSoft has been delivering IoT software development services since 2012, delivering custom enterprise software and developing MVPs for startups to gain a competitive advantage and improve their efficiency, effectiveness, and profit through business digitalization.

The SumatoSoft team has built 250 custom software solutions for 27 countries for 11 industries. After more than 13 years on the market, the company became a reliable technical partner to its Clients, demonstrating a 98% Client satisfaction rate with the quality of services they provide. Contact us to get a free quote for your project.

References

- Yasar K., Gillis AS. Internet of Things (IoT). Tech Target. https://www.techtarget.com/iotagenda/definition/Internet-of-Things-IoT. 2023.

- Ahmetoglu S., Che Cob Z., Ali NA. A systematic review of Internet of Things adoption in organizations: Taxonomy, benefits, challenges and critical factors. Applied Sciences, 12.9 (2022): 4117.

- Shiklo B. IoT: A technological advancement for oil and gas. Science Soft. https://www.scnsoft.com/blog/iot-in-oil-and-gas. 2025.

- Akpan, UE. Internet of Things in Petroleum: A Review of Benefits and Challenges. Journal of Engineering Research and Reports, 27,4 (2025): 411-425. 2025.

- Storts B. How satellite IoT is transforming data capture for oil and gas. Wyld. https://wyldnetworks.com/blog/satellite-iot-for-transformingdata-capture-oil-and-gas. 2025.

- Taherdoost H. Security and internet of things: benefits, challenges, and future perspectives. Electronics, 12.8 (2023). 1901.

- Sharma A. IoT in the oil and gas industry: Benefits, applications, challenges, and possible solutions. Appinventive. https://appinventiv.com/blog/iot-in-oil-and-gas/. 2025.

- Sharma SK., Rani A., Bakhariya H., Kumar R., Tomar D., Ghosh S. The role of IoT in optimizing operations in the oil and gas sector: A review. Transactions of the Indian National Academy of Engineering, 9,2 (2024): 293-312.

- Kumar K. IoT: Technological advantage for oil and gas. Fusion Informatics. https://www.fusioninformatics.com/blog/iot-technological-advancement-for-oil-gas/. 2024.

- Halsey T., Agrawal G., Bailey JR, Balhoff M., Borglum S., Mohanty KK, & Traver MT Grand Challenges for the Oil and Gas Industry for the Next Decade and Beyond. Journal of Petroleum Technology, 75,7 (2023): 52-56.

- Dziuba A. (2025). IoT in oil and gas: Transforming the sector with smart tech solutions. Relevant Software. https://relevant.software/blog/iot-in-oil-and-gas/. 2025.

- Sierra Wireless. Connected oil and gas. https://www.sierrawireless.com/industries/energy/oil-and-gas/. 2025.

- A Team Global. IoT for oil and gas industry: Advantages, features, and use cases. https://a-team.global/blog/iot-for-oil-and-gas-industry-advantages-features-and-use-cases/. 2025.

- Biz Intellia. 7 ways how IoT is revolutionizing the oil and gas industries. https://www.biz4intellia.com/blog/7-ways-how-iot-is-revolutionizing-the-oil-and-gas-industries/. 2025.

- Allioui H, Mourdi Y. (2023). Exploring the full potentials of IoT for better financial growth and stability: A comprehensive survey. Sensors, 23,19 (2023): 8015.

- Daws R. Oil and gas industry sees rapid growth in IoT devices. IoT News. https://iottechnews.com/news/oil-and-gas-industry-rapid-growth-iot-devices/. 2024.

- Deloitte. Perspectives: Internet of things in oil and gas. https://www2.deloitte.com/us/en/pages/consulting/articles/iot-digital-oil-and-gas.html. 2025.

- Lee S. IoT applications in the oil and gas industry. IoT For All. https://www.iotforall.com/iot-applications-oil-and-gas-industry. 2024.

- Tayliyev A. (2021). IoT in oil and gas: Analyzing technology and use cases. DEV. https://dev.to/lanars_inc/iot-in-oil-gas-analyzing-technology-use-cases-dhd. 2021.

- Digi International. IoT in oil and gas: 4 use cases and advantages. https://www.digi.com/blog/post/iot-in-oil-and-gas. 2024.

Let’s start

If you have any questions, email us info@sumatosoft.com