IoT in Manufacturing: Trends, Benefits, Use Cases, and Implementation Challenges

Today , the manufacturing industry is all set to take advantage of digital technology, just like every other industry. Manufacturing firms are working on boosting their productivity by leveraging modern technologies, like blockchain software solutions, SaaS development, etc. One such innovative technology that has evolved over time is the internet of things or IoT. The Internet of Things is a system that enables users to connect their everyday objects with computers and smartphones thus allowing them to send data about their condition over the web even with remote access. IoT software development is a means to remodel existing business development strategies. According to a recent report from Fortune Business insights, around 62% of manufacturers used IoT in production in 2025.

In this article, we are going to highlight the booming IoT trends for manufacturing, its significance, use cases, and challenges one has to face during the implementation of this technology for manufacturing.

Why is the Internet of Things Important?

The Internet of things is a game changer for businesses. It is a disruptive technology that will change the way companies operate. It offers more than just convenience to businesses; it also provides insight into the systems that can help improve performance or address problems before they arise with an automated home setup.

The Internet of Things is said to be a significant technological advancement that will gain continuous popularity with time. It allows manufacturing sectors to automate processes, cut down costs by automating specific tasks, and improve the service delivery to customers providing transparency into transactions that have been made via connected devices. All these specifics are achieved without losing any functionality. Because of these exceptional IoT benefits, the popularity of the IoT stays in the headlines, and the revenue of the internet of things is also escalating. A report by Statista states that in 2020 the global worth of IoT was $389 billion, and it is forecasted that this revenue will reach one trillion dollars in early 2030.

The Internet of Things is said to be a significant technological advancement that will gain continuous popularity with time. It allows manufacturing sectors to automate processes, cut down costs by automating specific tasks, and improve the service delivery to customers providing transparency into transactions that have been made via connected devices. All these specifics are achieved without losing any functionality. Because of these exceptional IoT benefits, the popularity of the IoT stays in the headlines, and the revenue of the Internet of Things is also escalating. A recent report from Statista estimates that the global total annual revenue reached $419.8 billion in 2025.

IoT in Manufacturing in Numbers

The global market of IoT in smart manufacturing is continuously expanding. This increasing popularity is made possible with the introduction of technological breakthroughs like smart sensors, virtual and augmented reality.

In a recent analysis of Allied Market Research on the subject of IoT in manufacturing, it is stated that the global market size of IoT for manufacturing is on track to reach a height of $525 billion by 2027 with a growth rate of 22%.

Interesting facts:

The potential for growth of IoT in manufacturing in the upcoming years is high, while many are planning to boost expenditure on this technology. Some interesting facts explain this better:

- The first IoT device was made at Carnegie Mellon, a soda machine. This led to the development of the first-ever ATM with a connected IoT device.

- The Internet of Things is a powerful tool for municipalities. This concept has been implemented in a number of locations throughout the world including Shanghai, creating smart cities.

- The IoT data is so huge in numbers that a zettabyte measurement is dedicated for it.

- The IoT devices vary in size. Some may be as small and concise – like bugs or bees, while others could vary dramatically in size like that of industrial robots.

- Smart factories is a new popular term in this field. Look the video to learn more about it.

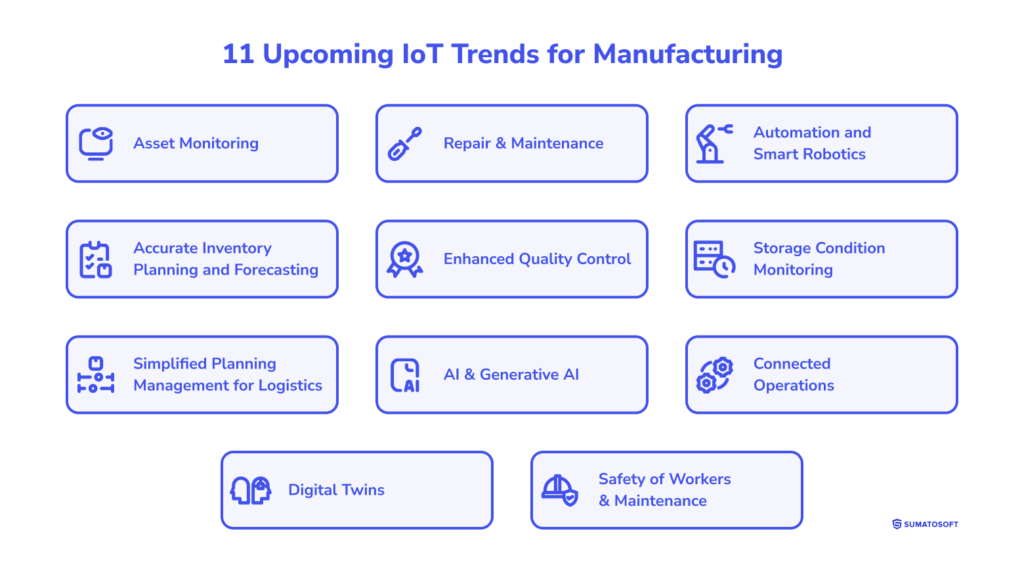

11 Upcoming Trends with Use Cases of IoT for Manufacturing

| Trend | Its essence |

|---|---|

| Asset monitoring | Sensors and GPS trace assets in real time, expose malfunctions early, and give history for smarter repairs. |

| Repair & maintenance | Machine data feeds predictive maintenance so faults surface in advance and downtime shrinks. |

| Automation and smart robotics | Connected robots and automated lines take over routine, repetitive operations, keep pace steady, and cut human error in harsh or monotonous tasks. |

| Inventory planning & forecasting | Live stock data and sales signals help foresee shortages and tune reorder levels instead of guessing. |

| Quality control | Scanners and sensors catch deviations in materials and products at the line, before defects reach the client. |

| Storage condition monitoring | Environmental sensors log temperature, humidity, and location so goods don’t spoil unnoticed in transit or warehouses. |

| Logistics planning management | Connected fleets and shipments show route, weather, and bottlenecks, letting planners avoid delays in advance. |

| AI & Generative AI | AI models sift sensor and process data, suggest optimal settings, generate reports or instructions, and help operators make decisions faster. |

| Connected operations | Linked machines exchange status in real time and can halt or adjust automatically when a step goes off spec. |

| Digital twins | Virtual copies of equipment replay real data, revealing abnormal behaviour and allowing safe “what-if” tests. |

| Worker safety | Wearables and IoT sensors notice hazardous conditions and unsafe patterns so crews get warnings before injuries happen. |

IoT Trend # 1: Asset Monitoring

Keeping secure and timely track of inventory and other assets is essential for businesses. Asset monitoring has become considerably simpler with IoT-enabled tracking. By allowing you to perform remote tracking of the asset, this technology helps your company to lower risk factors and develop the latest revenue sources.

Sensors and linked devices with GPS or GNSS are used in this IoT based asset monitoring systems to remotely manage and monitor an assets’ movement and location. These assets can either be home appliances, industrial equipment or vehicles.

Use Case: The SumatoSoft Company was tasked with making software that can be implemented in line with their client’s Big Data and ML solutions. Their main motive was to improve the client’s experience and keep track of their refrigerator’s issues. With the software developed by Sumatosoft, the client can monitor its refrigerator in real-time and be alerted if there is an emergency or problem. They will also have access to historical data on when repairs are needed so that these issues don’t go unnoticed for too long.

Why it matters: Sensor data can be used to improve your machine’s efficiency. Additionally, this integration with the internet of things will extend the lifespan of your electrical equipment/appliance. Through active IoT sensors, users can also receive an alert message instantly in case of urgency. This also lets them manage the historical data.

IoT Trend # 2: Repair & Maintenance Became Easier and More Precise

The internet of things is a significant tool for gathering information about the functionality of the machine. Data collected from connected devices and machinery can be used by applications to monitor operations in real time. Manufacturing facilities with IoT integration know when things go wrong. This anticipated prediction helps in lower customer costs and higher uptime.

Use Case: GE’s Pune is implementing IoT systems that provide predictive maintenance information via visualizations on a single screen to cut downtime for industrial equipment and save $1 million. Because of this, the equipment’s effectiveness has been increased to 15%.

Why it matters: Organizations may use the internet of things to reduce critical downtime and unnecessary effort by implementing predictive maintenance routines that will enable them to keep their equipment up to date. This means less time spent on repairs, which in turn saves money. One of the most significant trend of IoT in manufacturing.

IoT Trend # 3: Automation and Smart Robotics

Automation and smart robotics mean using robots, cobots, and mobile manipulators that “sense–decide–act” instead of just repeating one motion. They can adjust to part variation, change programs quickly for new models, and plug into MES/ERP and IoT systems, turning a rigid line into a configurable one.

Use Case: In automotive plants, cobots now handle glue application, door insulation, and paint tasks: workers position parts, while robots do the precise, repetitive rolling, spraying, or fastening that demands constant accuracy. BMW, Ford and others report that cobots take over the heavy or awkward work, while people focus on inspection and solving non-standard issues.

Why it matters: Smart robotics raise throughput and consistency while keeping unit costs under control, which is critical in price-pressured markets. At the same time, safer, collaborative robots ease physical strain and help close labor gaps, so factories can ramp up or reconfigure production without relying solely on scarce manual labor.

IoT Trend # 4: Accurate Inventory Planning and Forecasting

Manufacturing departments can make better forecasts for when inventory shortage occurs by carefully collecting and analyzing data. This forecasting helps them to plan out their inventory levels. Inventory planning enables procurement managers to decide what they need in order not only to save money but also to ensure efficiency throughout all manufacturing and purchase departments.

Use Case: Internet of things at ACE Hardware enables companies to track product orders and shipping status, thanks to IoT. These sensors provide real-time analysis of point-of-sale, which helps the ACE manufacturing team to replenish their inventory more quickly. This results in 24% increase in cost savings for holding items in stock.

Why it matters: The manufacturing department is always looking for ways to improve production ways, and for doing so, forecasting is an essential tool. By using data-driven strategies with current market conditions as well as forecasting results about how things will change over time, forecasters can develop plans based on what’s realistic instead of falling victimized by unknown factors or risks.

IoT Trend # 5: Enhanced Quality Control

Product managers can now track and monitor the quality of their raw materials, which will cut down on any potentially wasted money. IoT scanners can scan products to ensure they contain only high-quality goods that meet desired traits such as paint color or fabric composition before being put into production.

Use Case: One use case of this trend is implemented by Daihen Corporation. They have created an effective solution using outsourced internet of things through which they manage the quality of their industrial transformers. Their strategy involves the collection of multiprotocol streaming data from diverse assets to aggregate them all on one platform where they can be analyzed with real-time analytics.

Why it matters: The internet of things is a powerful tool that provides support in monitoring the production steps as well as equipment settings. This gives manufacturers a better chance to identify problems at the source, so quality mishaps are avoided.

IoT Trend # 6: Storage Condition Monitoring

The future of the supply chain is now at your fingertips. With IoT environmental sensors, GPS and other such devices can be used to track shipping conditions and product location. IoT for supply chain optimized the process of planning of transportation products, their storage facility conditions and detecting any imbalance. This results in proactive response to changes without ever having an issue with products going bad because of the bad weather or some other unfavorable reason.

Use Case: Sciencesoft data gathered from sensors are transmitted to the cloud, where customers can access them with an existing vehicle management system. This solution enables cargo temperature and humidity monitoring which helps all interested parties to monitor real-time condition of cargo during the entire shipping process.

Why it matters: The environmental sensors are small, eco-friendly devices that enable companies to monitor the physical conditions within the cargo trucks, and warehouses. They can also assist in monitoring the state of goods across the whole supply chain. These units help prevent money loss by providing accurate information about what’s happening within your company’s facilities and during the transportation of goods, so you can make informed decisions on how best to deal with it all.

IoT Trend # 7: Simplified Planning Management for Logistics

Companies involved in the logistics and transportation systems can make the interconnection of IoT-led between their systems and devices. Weather, fraud of assets, and improper management are few risk factors that manufacturing companies can overcome with the use of IoT technology for effective planning of the entire supply chain system.

Internet of things planning applications not only deal with supply chain management but also include tracking orders from the warehouse to the end customer, which plays an essential role in bringing digital transformation.

Use Case: FedEx company gets to know their package’s location during the journey with the help of Microsoft’s suite IoT technology. This IoT tells them about the location, weather conditions, and clearance issues and warns of natural disasters.

Why it matters: This will enable the company to avoid delays in the shipping of the orders and also helps them in forecasting the issues they can face while delivering the customer’s order. Hence, improving customer experience.

IoT Trend # 8: AI & Generative AI

This trend in manufacturing is known as Artificial Intelligence of Things in manufacturing (AIoT). It is about learning from data streams from sensors and business data to spot hidden patters, predict outcomes, and propose better solutions for the current supply chain structure. Consider them like analytics or very knowledgeable co-workers, capable to deal with massive amounts of data.

Use Case: Factories already apply generative AI to quality and design: BMW, for instance, uses AI-driven vision systems to catch tiny surface defects in real time, while firms like Bosch and GM experiment with genAI to generate and test thousands of virtual design variants before cutting any metal. Why it matters: AI compresses decision time: it helps engineers and managers see looming failures, quality drifts, or supply issues early and suggests concrete next steps, lifting OEE and trimming waste. Generative AI goes further, turning experimentation into a fast, low-risk digital exercise, so manufacturers can iterate on products and processes faster than rivals who still rely on slow, manual analysis.

IoT Trend # 9: Connected Operations Breaks Into The Industry

The operational performance of the manufacturing department can be improved by linking different machines and equipment together using IoT in manufacturing. This connected IoT network helps the manufacturing department in identifying the problems quickly by acquiring real-time data and contextual insights from assets operating remotely in different manufacturing units.

Use Case: Raytheon is a company that manufactures automated systems to use them for the collection of factory floor data to analyze it further. They have installed an IoT system that counts the screw turns of the missile plant at Huntsville. The screw needs to turn 13 times in the process, but they have connected the internet of things with their machinery so that the machine will stop working if the screw rotates 12 times only.

Why it matters: Internet of things in the operation department helps reduce cost since connecting with the machinery automatically tells about flaws machines have. This eliminates the need for extra labor that is usually required to monitor the equipment.

IoT Trend # 10: Digital Twins

The digital twins are the high quality virtual copies of actual physical systems that manufacturers use to monitor the equipment in real-time and gather information about the production process. It’s the most high-tech trend of IoT in manufacturing.

Digital twins allow manufacturers to create digital variants of the real world component being used in the manufacturing. This digital version compares the functionality and status of real world components and its interaction with other devices. This information helps manufacturers to effortlessly detect unforeseen behaviors, faults and usage spike earlier. The manufacturing teams can employ predictive maintenance for an equipment whenever an issue starts to build up. This enables businesses to avoid a hazard or production line halt.

Use Case: Kaeser is manufacturing a digital twin of its network compressors. They are employing the engineering base of Aucotec’s Software for this purpose. Thus, the real-time monitoring of operational data will enable specialists to foresee a system failure.

Why it matters: With Digital twining, the predictive maintenance process can be improved by using virtual replicas of actual machines. Digital twining of equipment and spare parts support managers to simulate the working environment of equipment with all involved physical processes and identify risks of failures before they occur without endangering actual assets.

IoT Trend # 11: Safety of Workers

Worker safety is a top priority concern in manufacturing factories. The introduction of the internet of things in the manufacturing environment significantly increases work safety. The IoT devices are able to spot potential dangers or injuries by measuring and forecasting worker’s behavior. Wearables of workers when connected with IoT sensors, transfer useful data to display and analyze how workers interact with their surroundings.

Use Case: FaceMe specializes in face recognition technology. Their system can determine whether an employee is wearing a mask or not.

Why it matters: This worker safety trend in IoT in smart manufacturing can facilitate companies in handling emergency situations more quickly. CO2 levels can be measured constantly to avoid fire risks. Moreover, working without stress improves workers’ health and productivity.

What can Go Awry: 4 Challenges of the IoT for Manufacturing

Now that we have covered all the good things about the internet of things for manufacturing. This section is structured to make you aware of some of its challenges as well.

Challenge # 1: Poor Security of IoT Devices

Giving a guarantee of the IoT system security is difficult because most smart devices have restricted computing power and are resource constrained. Therefore, running robust security systems on the internet of things is difficult. Other reasons which raise questions about the security of the internet of things are as follows:

- Access control is poor in IoT system

- The software does not get security patches with the time

- There are technical limitations on internet of things devices

According to aimprosoft, the security threats of the IoT system with the years passing keep increasing.

Challenge # 2: Privacy is a Serious Concern

Privacy is becoming the focus for IT experts nowadays, as cyber threats are increasing rapidly since the manufacturing related to IT increases. Unsecured communications and data storage are major concerns of security in IoT applications. Classified information can be acquired through compromised devices, and this is one of the critical situations that one faces in IoT privacy. An incident of cyber attack happened in 2017 in a casino where 10GB of private data was stolen by attaching a thermostat to a fish tank. Therefore, controlling the data leaks has to be addressed as soon as possible as it is one of the severe threats.

Challenge # 3: Skills Gap

Companies are still facing staffing and expertise challenges in IT, even in 2022. The event of COVID-19 has further disturbed the ecosystem, and because of that, companies are now facing more challenges. The survey conducted by Informa tech shows how many problems arise because of the skills gap within the organizations. 22% of respondents say that the skill gap complicates the internet of things budget, and 27% say that it affects project deployment. Other than this, PwC reports show that 74% of CEOs are worried about the presence of skills compared to 79% in the previous year

Challenge # 4: IoT Promises Big Returns, But ROI Calculation is Extremely Approximate

The main motive of introducing internet of things in the business is to eliminate the darker sides that are influencing the enterprise, like how to utilize assets properly, how the employee can be tracked and bring productivity, which tools are under stress, etc. The above-mentioned things cannot be measured in numbers; therefore, many company owners think they are not getting as much ROI as expected.

A Robust Internet of Things System Built with SumatoSoft

SumatoSoft has been building IoT solutions since 2012, helping enterprises and startups gain a competitive advantage and improve their efficiency, effectiveness, and profit through business digitalization.

SumatoSoft offers industry-focused solutions and AIoT development services for healthcare, retail, manufacturing, smart homes & cities, and automotive domains. These IoT solutions include remote patient monitoring, warehouse automation, fleet management, robotics, smart traffic lights, and more.

Every solution SumatoSoft builds comes with great security and scalability for future changes in terms of new features, fleet expansion, new users, and increased workload.

SumatoSoft IoT services include:

- All-around IoT Applications

- Connectivity Management

- Device Management

- Data Visualization

- IoT Data Analytics

- IoT Consulting

The SumatoSoft team has built 250+ custom software solutions for 27 countries for 10 industries. After more than 13 years on the market, the company managed to become a reliable technical partner to its clients, demonstrating a 98% client satisfaction rate with the quality of services they provide.

Being a manufacturer if you are seeking to create customized IoT-based solutions for your business, then our experts at Sumatosoft are up to assist you. Get in touch with us to flourish your business with IoT wonders!

Concluding Thoughts

With the introduction of the Internet of Things in the manufacturing department, massive growth has been seen in businesses. The IoT has given a lot of opportunities to companies that, by taking advantage of it, can maximize their profit and gain an outstanding advantage over their competitors. So this means that the internet of things is bringing transformation in the manufacturing sector, giving businesses various chances to grow in different directions.

Let’s start

If you have any questions, email us info@sumatosoft.com